Hi All

In this blog, I would like to explain the Quality Inspection configuration in EWM.

Helpful Reading:

- EWM 100 and EWM 120

- SAP Help - EWM QM

Configurations needed in EWM and ERP:

Please see steps in SAP Help Customizing Settings for QM in EWM - Quality Management (QM) - SAP Library

EWM Configurations in Detail:

Warehouse Independent/Global Configurations:-

Define external QM system (assuming business system for ERP is already defined) --> In case if you want to perform QI in EWM alone, skip this step.

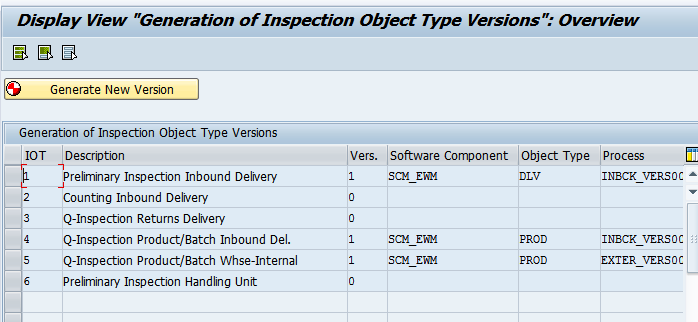

Inspection Object Type (Manual activity in each system)

Generate Inspection Object Type - select required IOT and click Generate

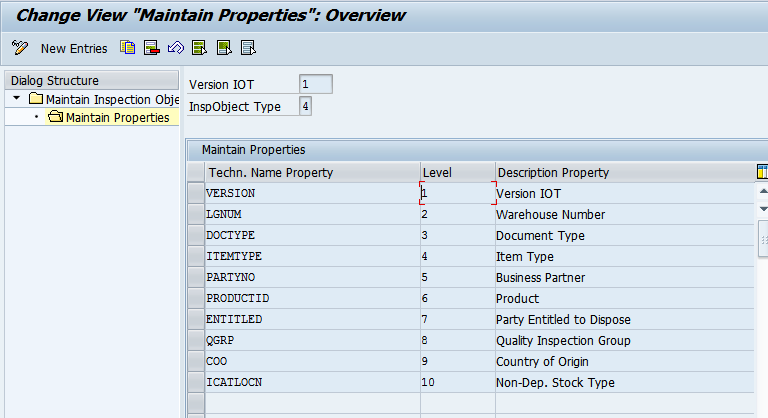

Maintain versions of Inspection Object Types and Properties

Define properties needed - these will appear in inspection rule; Also useful for inspection doc creation

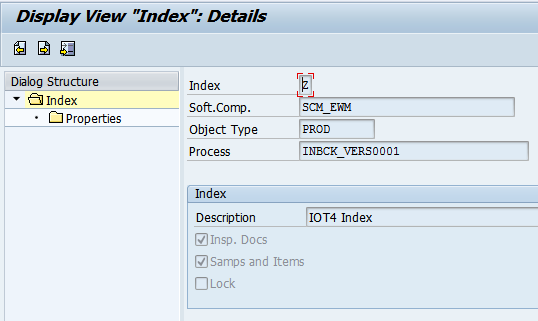

Define indexes

Inspection Document

Create Number range Groups

Create number ranges to cater different IOTs

Assign number ranges to groups

Sample Types/Item Types

Create number ranges groups

Create number ranges to cater different IOT related Samples/Item types

Assign number ranges to groups

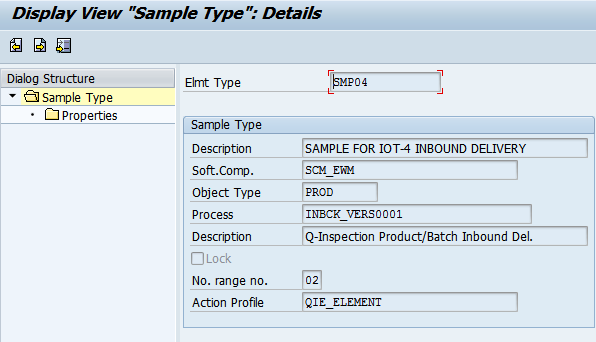

Define sample types

Define item types

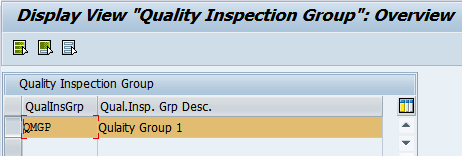

Quality inspection group

Define QIG - need to be in sync with ECC

Finding type

Create number ranges groups

Create number ranges to cater different IOT related findings

Define finding types

User decision

Define user decision codes - to be in sync with ECC

Define group

Group the codes

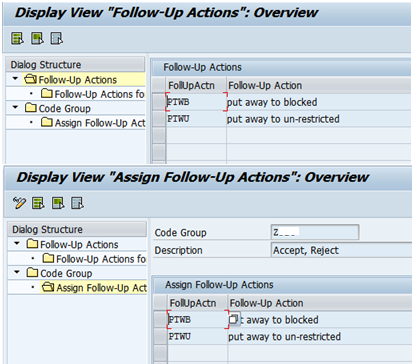

Define follow up actions and assign them to user decisions

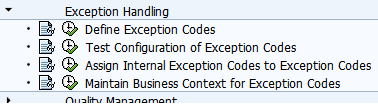

Define exception codes

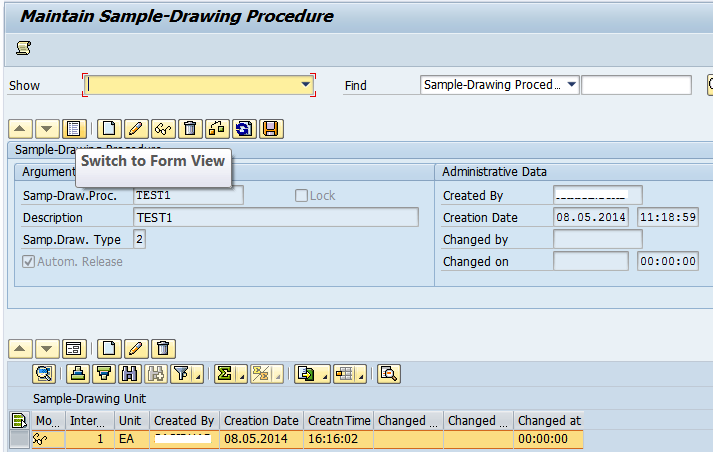

Sample Drawing procedure - EASY ACCESS/Master Data/QI

Warehouse Dependent Configurations:-

Maintain IOT for the Warehouse

Maintain follow up actions for WH

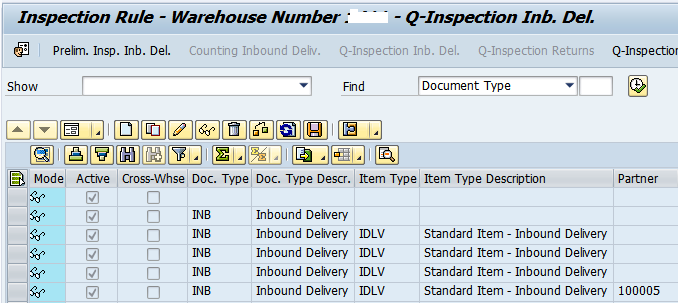

Create inspection rule - EASY ACCESS/Master Data - Manual activity in each system, can be uploaded using CSV.

Testing the configurations made:

1. Create inbound delivery in ERP and Distribute it to EWM.

2. Inbound delivery will be created in EWM automatically.

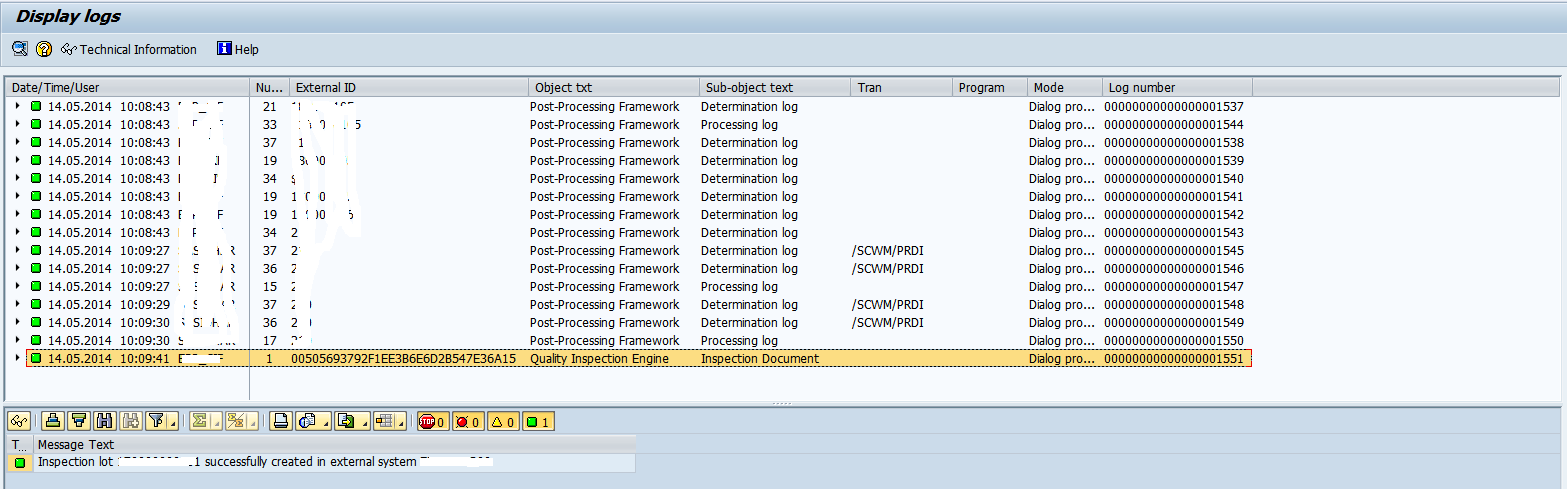

3. Unload and Post GR in EWM, QI document will be created in background. To validate this check the system logs in ECC and EWM.

ECC Logs:

EWM Logs:

For IOT-4, inspection document follows below statuses

- Created - at inbound delivery creation

- Released - after GR posting, notifies ERP

- ERP creates inspection lot

- Notifies QIE in EWM with lot# (event type linkages & BADI should be in place)

- Updated - EWM inspection document will be updated with inspection lot

Please check below threads also.

Hope this is helpful to you. Do let me know if you need any additional information.

Thanks

Sasidhar Gupta

- Page :

- 1