Conceptualization:

The blog is written to unravel the major differences between'' Delivery based Production and Advanced Production Integration and under what circumstances which model would be best for the business. This blog will also capture the discernible differences between the two.

Delta:

The below diagram gives perceptible delta between the two. I would accentuate and explain the major points only which gives a perspective picture for implementation considerations among the two.

All the key delta is already present in help.sap

The Warehouse and PSA can be connected with 1 EWM managed storage location, with 2 EWM managed storage location or with 1 EWM managed and 1 IM manged storage locations.

Note:-The 1 EWM and 1 IM managed storage location is specifically used for Repetitive manufacturing. I would explain latter why this set up of 1 EWM managed storage location for staging and 1 IM managed storage location for consumption is needed in case Repetitive manufacturing.

1.GR and GI of Semi finished products directly from PSA bin

Advanced Production Integration: This production model facilitates the provision of direct GR and GI of semi finished from PSA only. When production process has multiple phases and sub assemblies after being produced is consumed directly from PSA.

In a production where products are created in several stages(WIP), but the semi-finished products are not put away into the warehouse, goods receipt and consumption for the semi-finished product directly on the PSA bin. This shortens some warehouse activity.

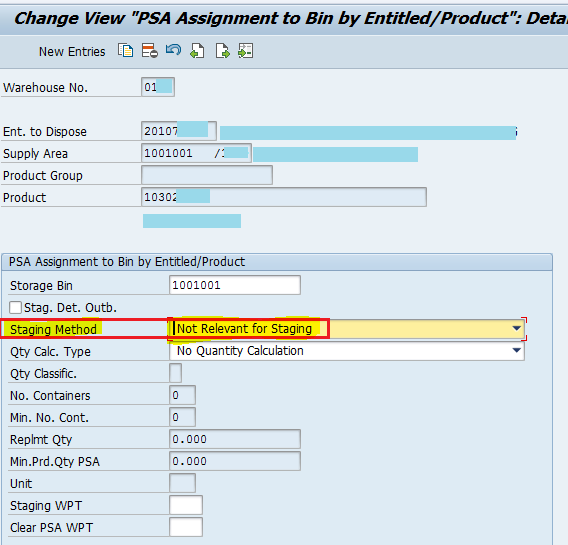

Use the staging method ''Not relevant for staging'' for products that are already on the PSA or for products that can be consumed from any goods issue bin.

If you want the system to determine the goods movement bin from the PSA, such as when you want to use exactly one bin for the goods movement, you can enter a storage bin in the settings for the PSA

Delivery Based Production Supply:

This functionality is not available in delivery based production model.

However, I used concept of Super Market in my previous project to map the GR and GI of semi-finished materials from PSA. An additional production supply area with fixed Bin needs to be created for such process.

Another concept which can be used to map this process is to use Collective order from PP.

Collective orders represent multilevel production structures for materials produced in-house in which the manufacturing order for the highest material in the structure automatically generates manufacturing orders for the semi-finished products in the structure. The output quantity of the manufacturing orders for the semi-finished products is the quantity required for the manufacture of the highest material. So, if sub assemblies GR is not relevant to business only GI, this model can be used in delivery based production.

2. Staging Methods:

Advanced production Integration: It supports lean manufacturing process thus keeping optimum inventory level in PSA. The staging of methods includes an arithmetic calculation of PSA stock minus requirement. Staging warehouse task quantity is based on the replenishment quantity field from PSA and not from the PMR item quantity.

In the PSA assignment ( transaction /SCWM/PSASTAGE ),the quantity calculation type = "2 Quantity based calculation". In this case the the logic for calculation of the proposed qty is based on the transaction /SCWM/PSASTAGE where the replenishment is set for qty of a given product/PSA/entitled to dispose etc

In case the existing quantity on a PSA is higher than the minimum quantity of the same material, no quantity proposal is made. Otherwise the demand quantity is compared with the existing quantity and in case the existing quantity is higher than the demand quantity a proposal of zero is made as there is no need for staging additional stock. In case the demand quantity is higher than the existing quantity the proposal is exactly as high as the defined replenishment quantity.

This behavior can be changed using badi /SCWM/EX_MFG_STAGE_INFO. With this logic, exact quantity of PMR can be staged and system doesn't look into the stock of PSA.

This staging method is useful for PSA which has space issue and keeping a optimum inventory level at PSA.

Delivery Based Production Supply: The system uses the full quantity of a reservation item (pick parts) or multiple reservation items (release order parts) for staging. This model doesn't look stock at PSA and stages components as per manufacturing order Quantities.

3. Other Manufacturing processes

Kanban and Repetitive Manufacturing.

If you want to implement JIT kanban and repetitive manufacturing considering you have takt based scheduling used in production, always implement ''Delivery Based Production''.

You use takt time and throughput time and line balancing concepts, use Delivery based production integration model to incorporate your requirement in EWM.

Advanced production integration using PMR doesn't support above production process for integration in EWM.

Repetitive manufacturing uses planned order with supply area information. Material staging for the components that are needed in production using an SAP EWM system. The components must be release order parts. The production storage location that you assign to the production supply area must be MM-IM managed in order to be selected in MF60.

For putaway in REM, you need enter a confirmation for repetitive manufacturing in the ERP system, via transaction MFBF using the physical data. If the receiving storage location is managed in EWM, the system creates an inbound delivery instead of posting the goods receipt directly. The inbound delivery is distributed to the EWM system where the goods receipt is posted and the material is put away.

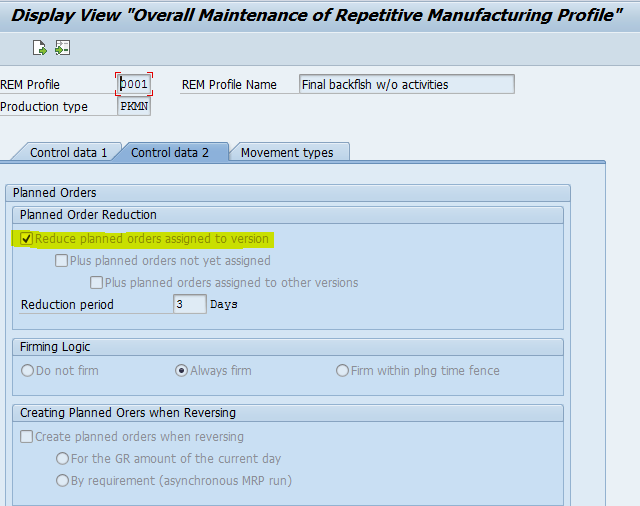

In classic repetitive manufacturing, the goods issue and the backflush are posted in a logical unit of work (LUW). As a result, the system reduces the planned order and its dependent requirements as per below settings. For this reason, the stock and the requirements situation are linked from the point of view of the planned order. If you post the goods receipt for repetitive manufacturing to an EWM-managed storage location, an inbound delivery is generated. The goods issues of the component are flagged instead of posted in ERP. If the goods receipt is posted in EWM, the system sends a goods receipt message to the ERP system. If the ERP system processes the message and updates the goods receipt for the inbound delivery, it processes the flagged goods issues. They are updated together with the goods receipt in an LUW so that the system adjusts the planned order and its dependent requirements simultaneously.

4. Date Determination in both the models.

Advanced Production Integration:

The system can map the dates for a component from the dates in the reservation item to the PMR item. The ERP interface maps all dates that are configured in the date profile (IMG Extended Warehouse Management -> Cross-Process Settings -> Delivery - Warehouse Request -> Dates/ Times -> Define Date Profiles) of the item type. The only data that is mandatory to be used is Requirement Start Date for Component

(SCMPREQ). All other dates are optional.

The system uses the Requirement Start Date to select the PMR items for staging. However, this date is not relevant for any follow up actions like creation of Warehouse task on that date.

Note: If you have some own logic from which you can set the date, you can use BAdI /SCWM/EX_MFG_STAGE_WT_CO (cross-order staging) or /SCWM/EX_MFG_STAGE_WT_SO (single order staging).

Delivery based Production:

The requirement date calculation of components in delivery based production supply model happens for Reservation date of items. The requirement date of components is fetched from Start date of header material from manufacturing order.

With the relevant configuration of Production order type and plant, system uses scheduling parameters of production orders to calculate the requirement date of dependent requirements( Components which are relevant for staging via delivery from Warehouse to PSA.)

However, if you want to influence the requirement date of components other than basic date, you need to use ''Lead Time Offset'' concept in BOM. Usage of this, can push(+) and Pull(-) the component dates in manufacturing orders.

5. Shuttle Process with Delivery Note:

The shuttle process with delivery note is primarily deployed when you have 2 separate EWM managed warehouses say W001 and W002 and PSA stocks are managed in SAP EWM in another warehouse

The staging takes place in a two-step posting change:

Of the outbound delivery from the sending SAP EWM warehouse(W001)

Of the inbound delivery to the receiving SAP EWM warehouse(W002)

So, this process can only be mapped using delivery based production not with advanced production integration.

The staging methods can be done in 3 different ways as below diagram.

- Via Pick parts

- Via release order Parts

- Via Kanban

I will explain the 3rd one, the 2 Step Kanban(K313) using outbound and Inbound delivery.

As the replenishment strategy for Kanban process under Shuttle environment, use a two-step stock transfer with delivery from a storage location that is managed by Extended Warehouse Management (EWM). When the distributed outbound delivery is confirmed in EWM, the goods issue of the outbound delivery is triggered in the ERP system. When this happens, the status of the kanban is set to "full", even though the quantity is only posted in the stock in transit.

In configuration use

- Kanban and the stock transfer with delivery replenishment strategy.

- The supply source storage location is managed by EWM.

Use delivery type determination customization using 2 step stock transfer GI and GR with movement type 313 and 315

6.Consumption & Backflush:

Delivery based Production:

All options available in SAP ERP to enter the consumption for an order, for example, transaction MIGO, or backflush(CO11N, COR6N). The system creates a consumption posting delivery in SAP EWM. The resulting outbound delivery order is not relevant for picking.

You can configure the system so that it posts the goods issue automatically when SAP EWM processes the message from SAP ERP.

Post GI for CP delivery.

Action Definition: /SCWM/PRD_OUT_POST_GI_PP

Assignment of Stock to the Goods Issue Bin:

If multiple suitable stocks are in a handling unit in the goods movement bin in an unpacked state, the system uses the (BAdI) /SCWM/CL_EI_CORE_PROD_STOCK to select a suitable stock.

In the standard implementation, the system sorts all stocks of the PSA using the first-in first-out (FIFO) principle.

You can implement /SCWM/EX_CORE_PROD_STOCK to sort the stocks at the PSA for consumption posting according to the following criteria:

Sort the stocks per delivery item

Reduce the quantity of stock items

Delete stock items from the list

If this badi is not implemented, then SAP uses the below fallback class for sorting Stocks of the PSA

Advanced Production Integration:

When a material is set as backflush item in the manufacturing order, you cannot enter the goods issue in SAP EWM. This is restriction.

However, for cross order staging, hybridization can be done. There is option to stage material via PMR but consume via backflush.

When you enter a backflush in SAP ERP, SAP ERP creates a consumption posting delivery, as described in consumption for delivery-based production supply. You can configure the system so that it adds the goods issue document to the respective PMR item as well as to the consumption posting delivery.

In OPC delivery, you can mark ''Update PMR. This settings passes same information for all items in the PMR.

This setting updates the goods issue document for the outbound delivery item to be documented in the corresponding production material request as well as in the outbound delivery,

This setting is only relevant when you use production material requests in staging for production and you enter the goods issue in the ERP system

Very important:

The system needs a reservation as reference document on the outbound delivery order item for the update of the production material request. You can activate this reference document category in the Customizing activity.

In standard system, it is by default inactivated, so you need to activate the reservation as reference document to update the backflush quantities in PMR

7.Stock Separation and ATP Check in delivery based Production.

The ATP check is carried out only on plant level, storage location level, batch level and batch/storage location level. ATP is not conducted at storage bin level, so we need storage locations for stock separation.

For better and transparent ATP, create 2 separate storage locations for Warehouse and PSA.

Cause:If you need to have ATP conducted at only Warehouse storage location level, you must create 2 separate storage locations so that ATP at production order of BOM items triggers at 1 storage location not at Plant level. The PSA storage locations can be excluded from ATP check at production order level.

If you have only 1 storage location, ATP in production order will confirm stock of( Warehouse+PSA stocks).

So, If you set the 'No storage location inspection' flag in the scope of check (transaction OVZ9), and you also set the MRP indicator (1 or 2) in the material master (transaction MM02, MRP 4 view, field DISKZ), during the creation/modification sales, purchasing, production orders or delivery documents the system will check ATP quantities on storage location level, without taking into account available quantities on plant level.

8.Batch determination and ATP check

As already stated, the availability check is carried out on all four levels (plant, storage location, batch, batch/storage location). During the batch determination storage locations are selected and therefore the availability must be checked for batch/storage location. If requirement is to have batch determination only from Main storage location( Warehouse storage location), then it would be recommended to have different storage locations.

If you have no batch determination set up in ERP, then there may be trouble of staging and consumption of Batches from EWM.

EWM does not know a batch determination.

Automatic batch determination during outbound delivery creation runs without specific batch selection, but does only replicate the batch selection criteria to SAP EWM, where then a batch search is executed.

Only characteristics that were selected as batch selection criteria(COB1, VCH1)either via the batch selection class or manually when creating the outbound delivery or sales order, are sent to SAP EWM and distributed.

When the WT is then created, EWM will only select quants with the proper batch.

For consumption:

Assume you have production order 1. You first get the delivery for staging. Assume you have the batch determination strategy running in ERP and the criterion is Expiration date, shelf life" (LOBM_VFDAT). You stage this material. But this can be any batch then with the criteria LOBM_VFDAT.

Then you have a second production order, same criteria, but this time another batch in EWM is selected (still criteria LOBM_VFDAT, but the first batch is not there anymore).

Now you post the consumption for any of these two production orders - which of the two batches should be used? Then here is conflict in consumption of batches.

So, it is recommended to have batch determination in manufacturing orders in ERP not in EWM.

Hence the blog ends here. I tried best to keep it short, but since extremely big topics were required to be covered, so it is large. Well, i have only included major differences between 2 integration models, there are many more differences which is available in help. sap site.

Any suggestions to make this blog more productive would be welcome.

Thanks to author Shailesh Mishra