What is cartonization planning in EWM Warehouse shipping through Wave process?

Hi Philippe

Not sure if I got your point correctly, but I think what you mean is regarding the pack specification sequence. You will be able to define what sequence the product should follow in order to the define the box1, box2 or box3. Follow one example in the configuration attached.

Hope it clarifies your doubts.

best regards,

/Flavio Marcilio

Hi,

in the algorithm profile is a flag to “check dimensions”, so dimensions can be considered.

What the standard algorithm delivered by SAP can not do by itself, is a nested packing (if this is what you are asking). For this you have to define your own algorithm (the algorithm is always an implementation of the BAdI /SCWM/EX_CAP_ALGORITHM).

Brgds

Juergen

Hi Flavio,

Great post.

Small question regarding scenario 3.

When i see the dimensions of the product, i see that the box 3 can’t enter in the small box. Is the algorithm of SAP only looking at volume and weight? not the dimension of the product.

Philippe

Purpose:

In shipping, cartonization is a process that evaluates items in an order to determine the number and size of each carton needed to ship the order.

In traditional packing environments, employees choose the boxes themselves or use order-fulfillment software to select the boxes. Cartonization automates and improves traditional manual shipping methods by saving money and reducing waste. For example, using cartonization can reduce the need to fill voids in boxes, result in less damage because goods are packed and shipped more efficiently and reduce overall shipping costs because packaging weights are reduced.

You can use cartonization planning to improve the creation of shipping handling units (HUs) based on information from product master data and outbound delivery orders, such as quantities, volume, and weight. Cartonization planning results in the creation of planned shipping handling units (PSHUs) that you can use as templates for creating shipping HUs during picking or packing

Overview:

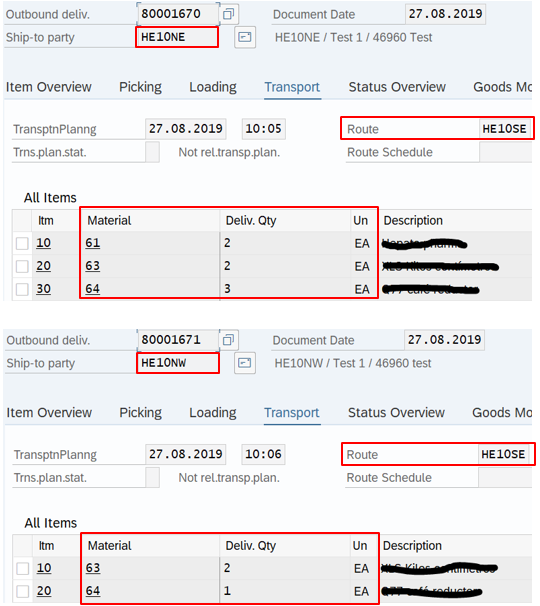

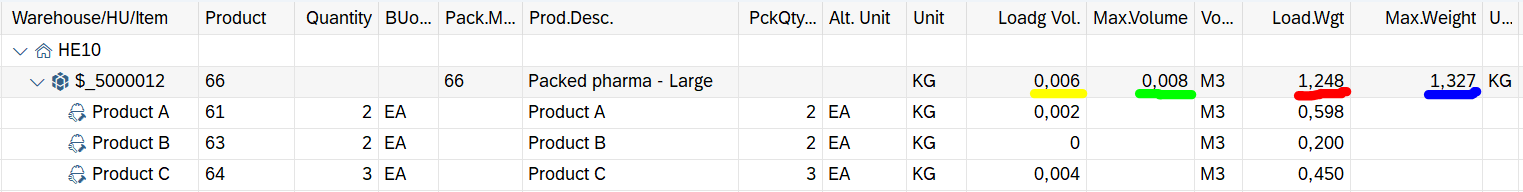

The scenario described below is covering three customers with the same route. There are also three products and three sizes of cartons which will be automatic defined according to the volume & weight capacity.

The EWM process steps starts with an automatic wave assignment based on the customer´s route as well as an outbound process oriented storage control with 2 steps (pick and pack).

Scenario 1:

- Customer HE10NE, products A,B and C with volume & weight capacity for large boxes.

Scenario 2:

- Customer HE10NW, products B and C with volume & weight capacity for medium boxes

Scenario 3:

- Customer HE10SE, product A with volume & weight capacity for small boxes

Step 1 : Customizing

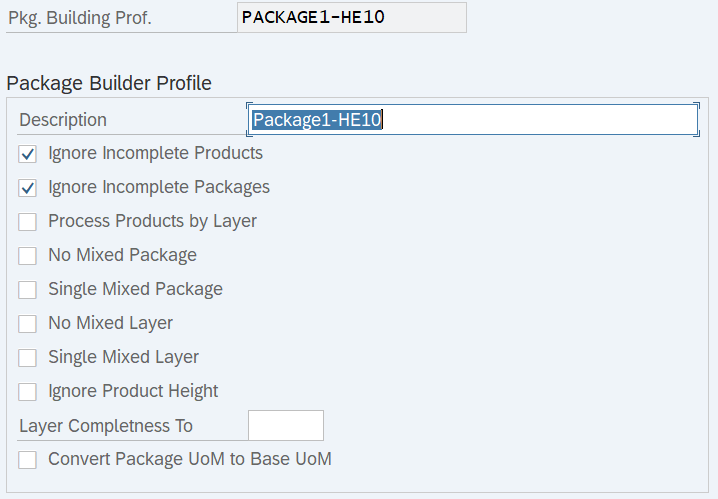

Define package bulding profile

SPRO –> IMG –> EWM –> Goods issue process –> Cartonization planning -> Define package bulding profile

Define number ranges for identification of PSHUs

SPRO –> IMG –> EWM –> Goods issue process –> Cartonization planning -> Define number ranges for identification of PSHUs

Configure cartonization planning on warehouse number level

SPRO –> IMG –> EWM –> Goods issue process –> Cartonization planning -> Configure cartonization planning on warehouse number level

Define algorithm profiles for cartonization planning

SPRO –> IMG –> EWM –> Goods issue process –> Cartonization planning -> Define algorithm profiles for cartonization planning

Define access sequence of algoriyhm profiles

SPRO –> IMG –> EWM –> Goods issue process –> Cartonization planning -> Define access sequence of algoriyhm profiles

Define process profiles for cartonization planning

SPRO –> IMG –> EWM –> Goods issue process –> Cartonization planning -> Define process profiles for cartonization planning

Note. This blog describe "Cartonization planning for waves"

Determine process profiles for cartonization planning

SPRO –> IMG –> EWM –> Goods issue process –> Cartonization planning -> Determine process profiles for cartonization planning

Define packing profile for warehouse order creation

SPRO -> IMG -> EWM -> Cross-process settings -> Warehouse order -> Define packing profile for warehouse order creation

Define creation rule for warehouse orders

SPRO -> IMG -> EWM -> Cross-process settings -> Warehouse order -> Define creation rule for warehouse orders

Define search sequence of creation rules for activity areas

SPRO -> IMG -> EWM -> Cross-process settings -> Warehouse order -> Define search sequence of creation rules for activity areas

Define process-oriented storage control

SPRO -> IMG -> EWM -> Cross-process settings -> Warehouse task -> Define process-oriented storage control

Define warehouse process type

SPRO -> IMG -> EWM -> Cross-process settings -> Warehouse task -> Define warehouse process type

Define control indicators for determining warehouse process types

SPRO -> IMG -> EWM -> Cross-process settings -> Warehouse task -> Define control indicators for determining warehouse process types

Determine warsehouse process type

SPRO -> IMG -> EWM -> Cross-process settings -> Warehouse task -> Determine warsehouse process type

Define work center

SPRO -> IMG -> EWM -> Mater data -> Work center -> Define work center

Step 2 : Master data

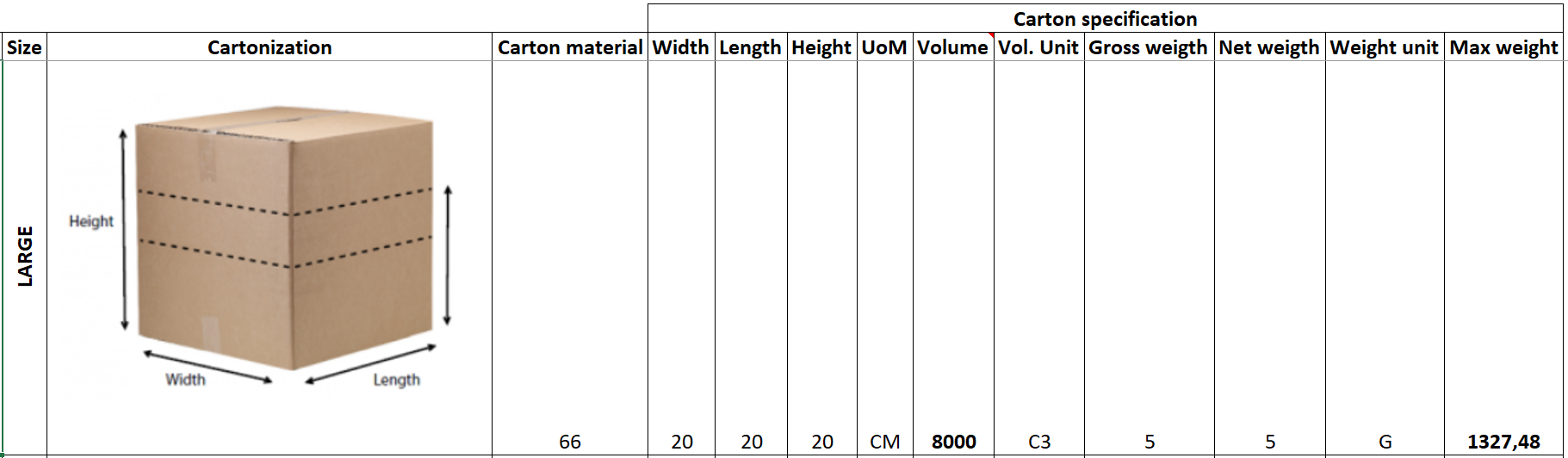

Maintain pack specification 3 times for each pack material described below.

- Material “66“ – cartonization large

- Material “67“ – cartonization medium

- Material “68“ – cartonization small

t.code : /n/scwm/packspec

E.g. packspec “517“ assigned to pack material “66“

Determine algorithm profiles for cartonization planning

t.code : /n/scwm/cappdet

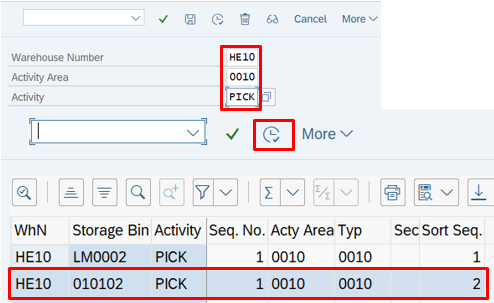

Assign start/end storage bin for activity area

t.code : /n/scwm/seba![]()

Sort storage bins

t.code : /n/scwm/sbst

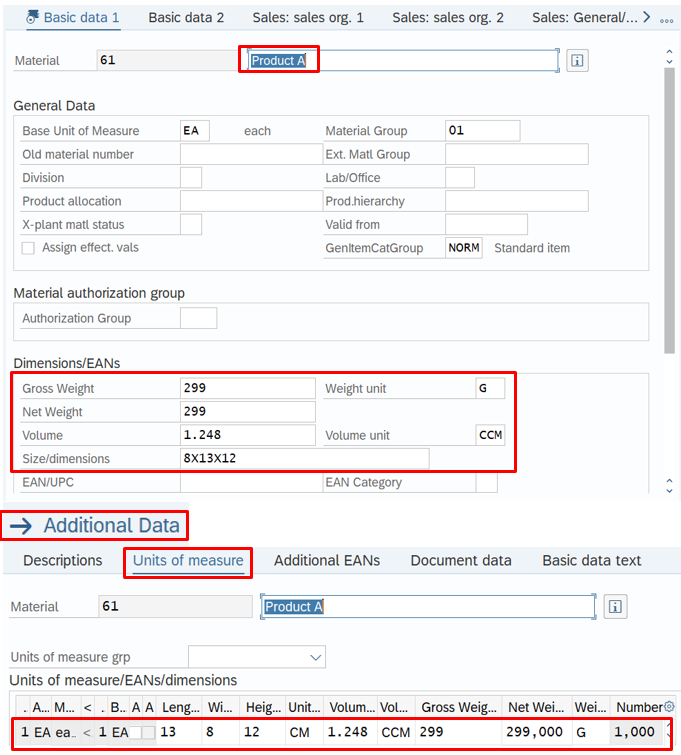

Maintain material master data

t.code : MM01 (ERP)

- “Product A“

- “Product B“

- “Product C“

Maintain pack material (material type VERP)

t.code : MM01

- “ Packed pharma - Large“

- “ Packed pharma - Medium“

- “ Packed pharma - Small“

Step 3 : E2E Process

Sales Order (ERP)

t.code : VA01

Outbound delivery (ERP)

t.code : VL02N

note. All of them is assigned to the same route.

Automatic wave assignment

t.code : /n/scwm/mon

Cartonization planning for waves

t.code : /n/scwm/capwave

Note. You can also activate cartonization planning log, as follow:

Easy SAP menu -> EWM -> Settings -> Application log -> Active application log (/n/scwm/actlog)

Subobject : "CAP"

*** Cartonization planning results

T.code : /n/scwm/cap

Wave released and picking step (CAR1)

t.code : /n/scwm/mon

Packing step (CAR2)

t.code : /n/scwm/pack

Then, after the packing step it would follow the standard loading and goods issue processes.

References :

https://help.sap.com/saphelp_ewm900/helpdata/en/9a/9394774d164a4386c5a03124df9be4/frameset.htm

https://help.sap.com/saphelp_SCM700_ehp02/helpdata/en/36/17ca418c4e4bea96b304726d94231f/content.htm?...

https://searcherp.techtarget.com/definition/cartonization

CREDIT TO: Flavio Marcilio - EWM Consultant

- Page :

- 1