In this post, I would like to explain different cases when cancelling Inbound Goods Receipt process with EWM for both case entire Inbound cancel and partial Inbound cancel.

Overview EWM Inbound process

This is process flow of simple Inbound process with direct putaway step.

Note: Inbound delivery Notification is created when using Decentralized EWM, but it's not mentioned in this process.

Overview EWM Cancel Inbound process

Let’s focus on steps of EWM from step 1 to step 4, we have different cancel cases as below.

Depends on which step has been done when performing Goods receipt, we have different cancel steps as below.

This session shows how to cancel the entire Inbound Delivery.

Case 1: It is quite simple here, EWM Inbound delivery is auto created by the system and no action is yet happen. We can simply Reject the Inbound here.

Case 2: GR is posted but no WT is yet created, we need to reverse GR first, and then Reject Inbound delivery.

Case 3: GR is posted, WT is created, but WT is still open and not yet confirmed. We need to cancel WT first, then reverse GR and finally Reject Inbound delivery.

Case 4: It’s impossible to cancel anymore if WT is confirmed and WT confirmation is sent to update inbound delivery in ERP side. The process Return to Vendor must be applied - see my blog about this process here Link

Note: In case 4 if you have defined a completion delay for inbound deliveries, the system allows user to modify/update the quantity received after WT is confirmed if the time delay has not exceeded. - In detail, see this blog Here

Testing – Case 3 (Entire Inbound Delivery Cancel)

Because it’s sharing same steps among the cases, I will test Case 3 which cover all steps.

Check data before cancelling

♦ ERP Inbound, Goods movement Status: Completed

Tcode: VL33N

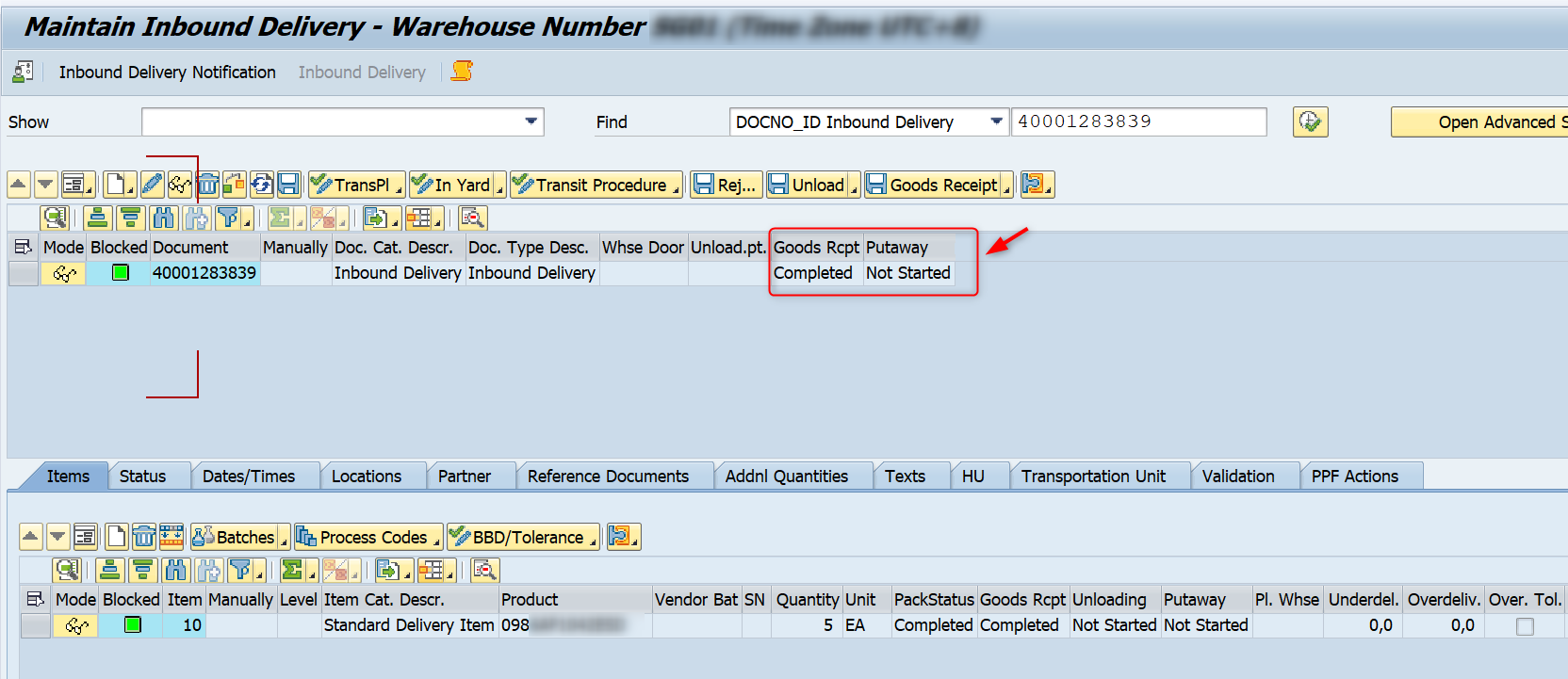

♦ EWM Inbound, status GR - Completed, Putaway - Not Started

Tcode: /SCWM/PRDI

♦ WT is created and Status is Open

Tcode: /SCWM/TO_CONF

♦ Check stock is at GR-ZONE

Tcode: /SCWM/MON

Cancel Inbound Process

Step 1: Cancel WT

Tcode: /SCWM/MON or /SCWM/TO_CONF

Cancel WT with /SCWM/MON

Another option is cancel WT with /SCWM/TO_CONF.

WT status is updated as Cancelled.

Step 2: Reverse GR

Tcode: /SCWM/PRDI

Select Inbound Delivery header and click on “Reverse Goods receipt”.

Verify that Goods Receipt status is now updated as “Not Stared”.

On ERP side, Inbound Delivery, status of Goods movement is updated as “A” – Not Started.

Step 3: Reject Inbound

Tcode: /SCWM/PRDI

Select Inbound Delivery header and click on “Reject”.

Verify that the Goods Receipt and Putaway status are set to "Completed" and quantity is reduced to zero.

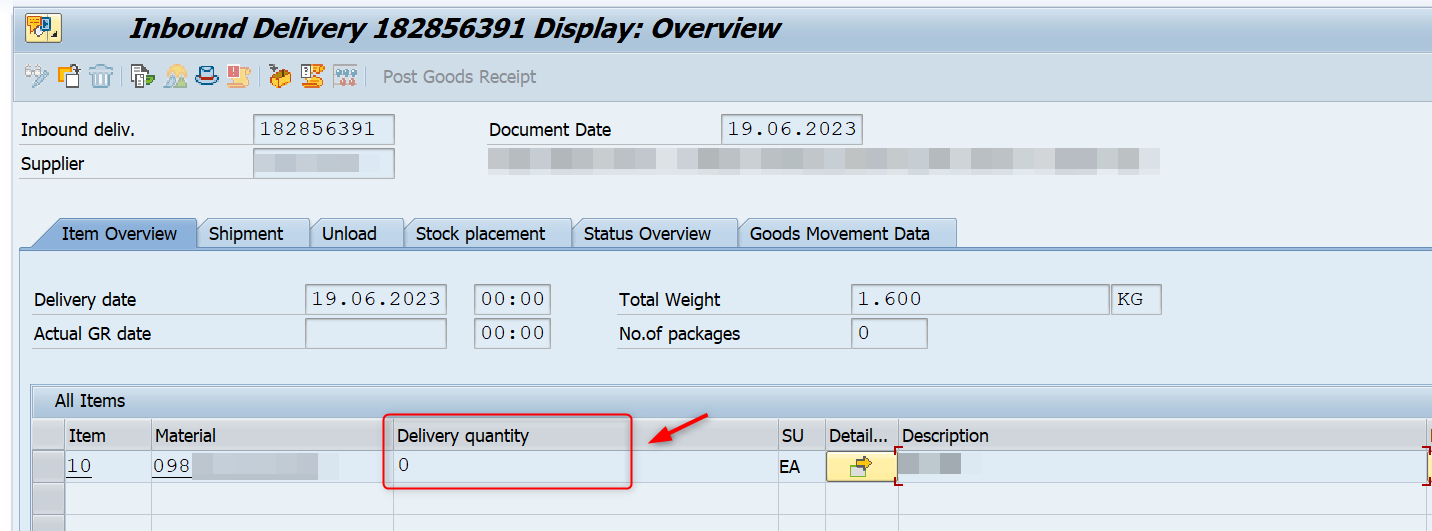

On ERP side:

- The quantity in the Inbound Delivery reduced to zero.

- The cancelled quantity was decreased from the received-on-dock stock.

- A new inbound delivery can be created from open Purchase Order Quantity.

Partial Inbound Cancel - Cancellation of inbound items

This process shows how to cancel inbound delivery item in different cases.

Case 1: GR is not yet posted, WT is not yet created

Adjust quantity of inbound delivery item to zero.

Note to unpack (empty) all HU before you can adjust the quantity.

>> Result: Inbound delivery Item GR status – Completed, Putaway status – Completed; item quantity reduce to zero.

>> On ERP: The quantity in the Inbound Delivery is adjusted to zero, Item Goods movement status is “C” – Completed.

Case 2: GR is posted, WT is created and WT status is open

Option 1: If you want to adjust only 1 item quantity, you can adjust quantity during WT confirmation with exception code. System will generate reverse material document for different quantity.

Tcode: /SCWM/TO_CONF - Confirm WT in foreground

Option 2: This way is possible but not recommend because you need to reverse all process just to adjust 1 line item. Adjust item quantity via WT confirmation is much affective.

Step 1: Cancel open WT for all items.

Step 2: Reverse Goods receipt

Note: It’s only possible to reverse GR if all item’s WT is still open. When WT of 1 item is already confirmed, reverse GR is not possible.

Step 3: Adjust quantity to zero to cancel the entire line.

Note to unpack (empty) all HU before you can adjust the quantity.

--- *END* ---

Thanks for reading. Hope this is helpful. I would like to receive any feedback/comment to improve my post.

Thanks to author Dang Bao Van