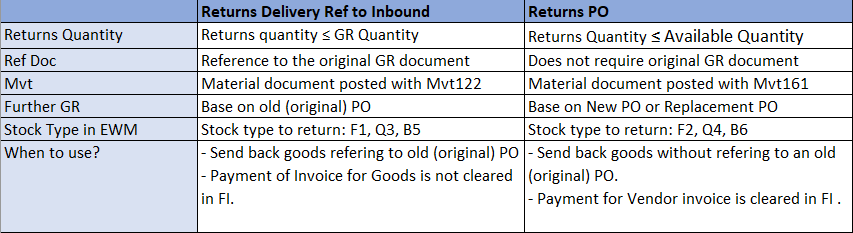

SAP offers 2 different processes of Vendor Returns: returns with Returns Delivery Ref to Inbound Delivery and returns with Returns PO. So what is the difference? In this blogs I will compare this 2 processes with EWM steps.

My Testing is based on Embedded EWM - S/4HANA 1909.

Compare Vendor Return Process with Returns Delivery Ref to Inbound and Returns PO

- Overall Process with EWM steps

- Comparation

Prerequisite

- Active BC Set - /SCWM/DLV_OUTBOUND_RETURN

Configuration

General Customizing

- Set up confirmation Control Key

IMG: MM > Purchasing > Confirmations > Set Up Confirmation Control

Assign 0004 as Quantity Difference Profile

IMG: MM > Purchasing > Confirmations > Set Up Quantity Difference Profiles (GR Automotive)

IMG: MM > Purchasing > Confirmations > Define Internal Confirmation Categories

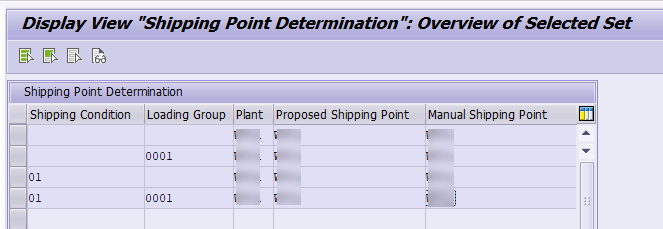

- Shipping point determination

IMG: Logistics Execution > Shipping > Basic Shipping Functions > Shipping Point and Goods Receiving Point Determination > Assign Shipping Points

- Define shipping data (For Returns PO)

IMG: Material Management -> Purchasing -> Purchase Order -> Set up Stock Transport Order -> Define Shipping Data for Plants

Need to create a BP as Customer for Plants and assign BP here.

- Check "Delivery Split" in delivery Type

IMG: Logistics Execution > Shipping > Deliveries > Define Delivery Types

- Delivery Item Type Determination

IMG: Logistics Execution > Shipping > Deliveries > Define Item Category Determination in Deliveries

EWM Customizing

- Mapping Delivery Type and Item Type S/4HANA & EWM

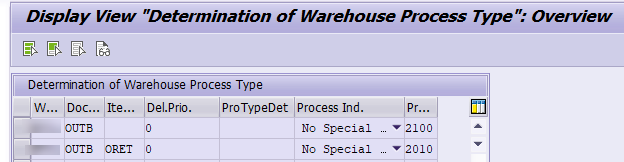

- Determine WPT for Return Doc Type

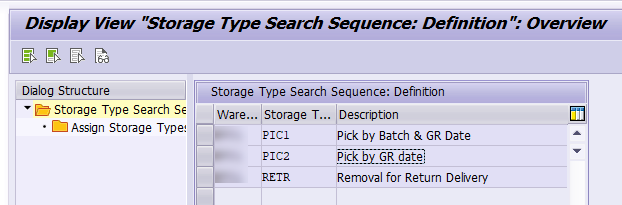

- Define Storage search sequence

Note: Assign GR Interims Storage Type 9010 to search sequence of Return Delivery

- Determine Storage Type search sequence

Master data

When using Returns PO, Vendor master data and Material Master data need some additional data as below.

- Vendor Master data:

For using Return Delivery, in Role Vendor, mark Vendor as Return Supplier.

For using Returns PO, maintain Customer roles for Sales.org & Distribution Channel. Assign Delivery Plant as plant where you returns stock.

- Material Master data:

For using Returns PO, maintain Sales View for material.

Testing

Vendor Returns - Using Returns Delivery Ref to Inbound Delivery

Step 1: Create Return Delivery Ref to Inbound

Tcode: /SCWM/PRDI

Before this step, a Inbound Delivery is created and GR is posted.

Stock is still in GR-ZONE, mean if you already putaway stock and confirmed putaway WT, you need manually transfer stock to GR Zone.

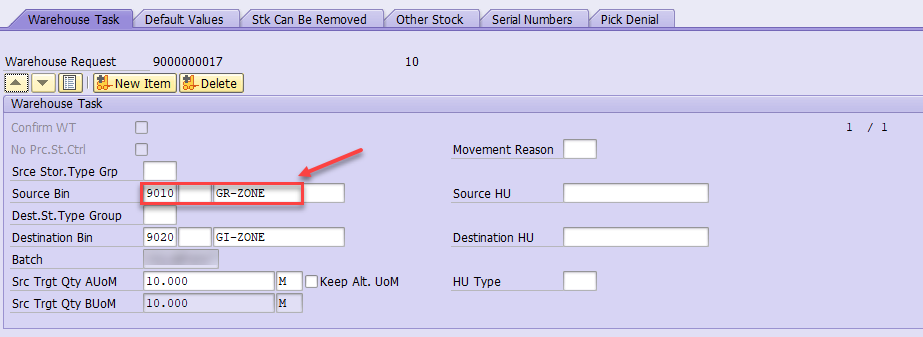

Step 2: Create Picking WT and Confirm WT

Tcode: /SCWM/PRDO

Note: Stock is taken from GR-ZONE to GI-ZONE

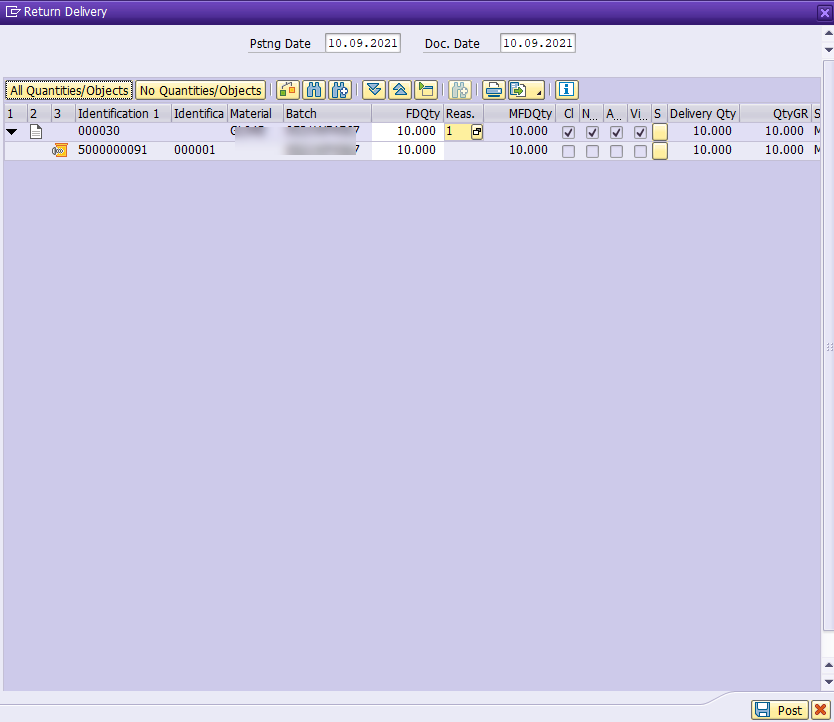

Step 3: Post GI

Tcode: /SCWM/PRDO

Post GI after picking is completed.

Note: Stock Type is Q3 (or F1)

Material Document with Mvt 122 is created in S/4HANA

Vendor Returns - Using Returns PO

Step 1: Create Retuns PO

Tcode: ME21N

Select PO type - PO Return and mark Item as Return Item

Step 2: Create Outbound Delivery

Tcode: VL10B

Step 3: Create Picking WT and Confirm WT

Tcode: /SCWM/PRDO

Step 4: Post GI

Tcode: /SCWM/PRDO

Post GI after picking is complete.

Note: Stock type is Q4 (or F2)

Material document is created with Mvt 161

*****

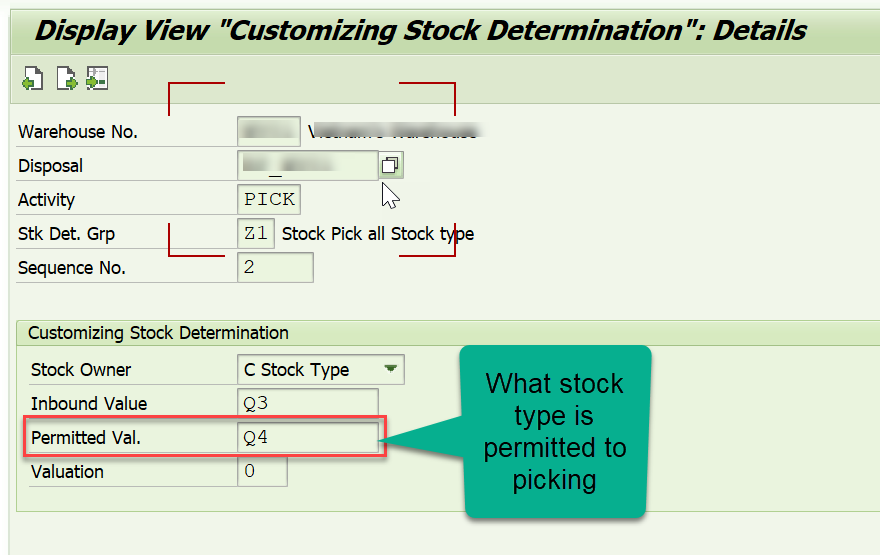

Important note!!!

If you want to return stock rather than your original GR stock type, you must set up Stock Determination for other Stock type.

Example: GR with inbound delivery, stock type Q3. But you want to return stock with stock type Q4 or F2, it's possible.

IMG: EWM > Cross process Setting > Stock Determination

Create a Stock Determination Group and Assign Stock Determination.

You can create many stock Determination to picking more than 1 stock type for return.

Next step to assign Stock Determination Group to your Product Master.

/SCWM/MAT1

--- End ---

In which case will you use Returns Delivery Ref to Inbound or Returns PO? Feel free to question/comment on my Topics.

Regards,

Thanks to author Van Dang

- Page :

- 1