Introduction

In some business scenarios, the warehouse requires to pick up the Full pallet to the GI Zone directly, and if any pallet which needs to be repacked that only brings it to Pick Point Work Center. The pallets not subjected to any repack should go directly to the GI zone and be loaded on TU or goods issued directly.

Below is the sample scenario and requirement discussed along with the solution approach considering Pick Point and LOSC / POSC usage.

-Storage Type ZUHR always stores full pallets. 1 Full pallet is equal to 10 EA.

-Storage type ZUHX is always stored partial pallet which comes from the pick point after repacking.

The business Requirement is to pick the pallet from high rack ZHUR and if the required delivery quantity is in multiple of full pallets, then choose pallets and send it to GI Zone.

If the required delivery quantity is not multiple of full pallet, then bring the last full pallet to Pickpoint, repack into new HU, and send back the original pallet (which is not full pallet after repacking) to another storage type ZVHX which holds all partial pallet only.

The below screenshot example shows the required delivery quantity is 27 EA. That is 2 Full pallets and one partial pallet to be delivered. The requirement is to pick 2 full pallets directly from ZVHR to GI zone and the last full pallet to bring to pick point work Center ZV82, repack into new HU, and send new HU to GI zone. After all, the above steps are done, send back the remaining pallet from the pick point to partial pallet storage type ZVHX.

Business Process Example

Solution Approach

In this section you will understand the configuration and important data setting required to fulfill the business requirements:

Source Storage Type & Pick point storage type configurations

LOSC configuration for this pick point.

WOCR to pick full and partial pallets.

Activate the pick point checkbox in source storage type ZVHR:

– SPRO -> IMG -> Extended Warehouse Management -> Master Data -> Define Storage Type.

Source Storage type

Define pick point storage type ZV82:

Pick Point storage type should have a storage type role as B – Pick Point

– SPRO -> IMG -> Extended Warehouse Management -> Master Data -> Define Storage Type.

Pick Point Storage Type

Define Work Center

Define a new work center for packing / Repacking at the pick point and mention the pick point storage type within it along with the POSC storage process.

Define Return storage type and Process type within the work center

– SPRO -> IMG -> Extended Warehouse Management -> Master Data -> Define Work Center.

Pick Point Work Center

Define LOSC setting to route pallets from the Source storage type to the GI zone via Pick point storage type.

– SPRO -> IMG -> Extended Warehouse Management -> Cross Process Setting -> Define Warehouse TaskàDefine Layout storage process control.

LOSC Setting

Define the Warehouse order creation rule and assignment of storage process to it

– SPRO -> IMG -> Extended Warehouse Management -> Cross Process Setting -> Warehouse OrderàDefine WOCR.

WOCR and Storage Process Assignment

Storage Process

Testing

Stock Before EWM Delivery and Picking WT created

EWM Stock Before Picking

Create Sales Order - 27 EA Qty -SO 138 Created (2 Full Pallet and 1 Partial Pallet)

Create Outbound Delivery - 80000206

ERP Outbound Delivery distributed to EWM- 310000000415

Create Picking WT for EWM Delivery

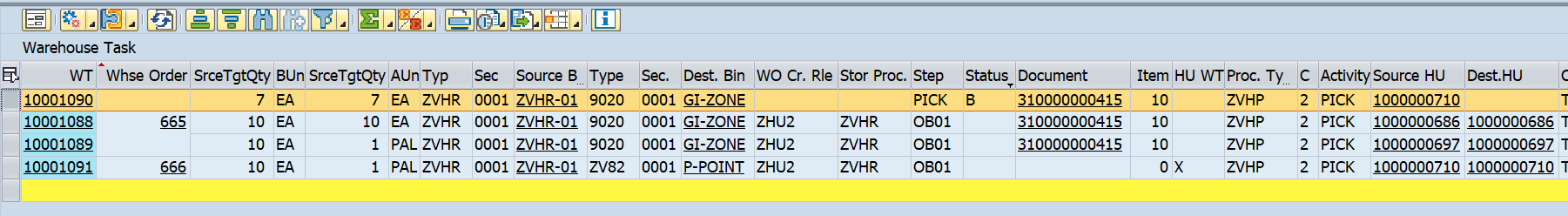

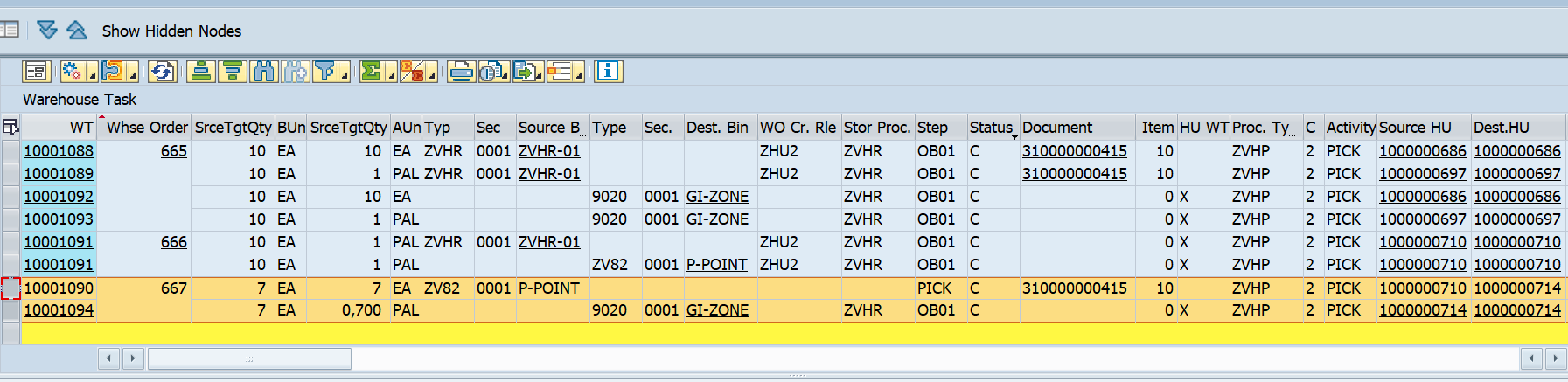

Two WO created – one WO to bring the full pallet to the GI zone directly and one full pallet to the pick point ( LOSC) and the last WT in waiting status from the pick point to GI Zone. As per the POSC setting OB01 step is determined first.

Confirm Picking WT from RF -Warehouse Order 665

- Confirm Picking WT from RF -Warehouse Order 666 to send a pallet to pick Point for Repack into New HU

- Confirm WT 10001090 - WO 667 to repack into the new HU and bring the new pallet to the GI zone

- send back the original pallet after repacking into Repack St Type ZPHX using /SCWM/PACK

Pallet 1000000710 will send back to return storage type ZVHX ( defined in Work Center via process type 3070)

- Goods Issue EWM Delivery

- ECC Delivery update with goods movement and HU

- EWM Stock after Goods issue

Conclusion

This blog post walks you through various steps involved in EWM stock picking via pick point considering full pallet should go directly to GI ZONE and pallet which is to be repacked for the remaining qty only passed via Pick Point Work Center.

Thanks to author Bansod Vaibhav V