This blog post is intended to provide the reader, complete details about SAP EWM Pallet storage strategy by HU Type.

As per configuration of this Pallet storage , system allow to store different HU types to a suitable storage bin section. Main storage bin is divided into several smaller Sub bins and this strategy enables Put away activity for different HU types into Sub bins.

This strategy Defines number of quants for each combination of storage bin type and HU type.

First time the Put away happens in a bin, system determines storage bin section and assigns it to a bin. System also determines how many HU’s can be put away in a bin.

The Pallet Put away is configured for Storage type with Storage Behavior – 1 set in the storage type Definition.

The additional checks needs to configured HU type check , Put away rule – 5 (Empty bin value).

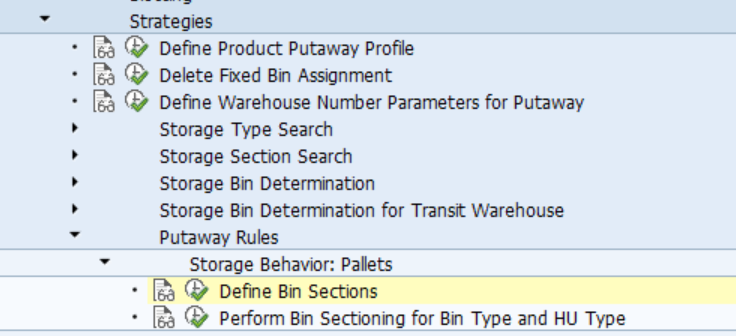

Next you need to define storage bin section.

Storage bin section Key is configured to determine how many Handling unit’s of different HU types can be placed in a bin. The storage bin section is a key which is alphanumeric and it is configured with no of HU’s which can be put away.

In the below screen shot , For warehouse – 1100 , Storage type – B300 , storage bin section 1 to 8 are configured with different Storage bin type – B203/B204/B303/B304 etc. and value in Column ‘Max No of HU’ which helps to determine the Max No of HU’s those can be placed in a bin.

Further Bin position is a suffice that system attaches to Main bin to determine the naming convention of Sub bins.

The Main bin is divided into Several sub bins. This sub bins are created when the First put away activity happens in bin.

In the below example , the Storage bin type -B303 has bin position – 1 , 2 , 3. If the name for main bin is 01-01-10. After first pallet is put away in this Bin type type B303 , following three sub bins will be created.

01-01-10/1

01-01-10/2

01-01-10/3

The suffix entered in the Bin position Is used to create Sub bins. Name of Sub bin is determined by adding Slash(/) to the main bin.

The Section key is added to the combination of Storage type , Bin type & HU type.

If configuration is done for one Bin type with different HU type to have the same Storage bin section key then system allows the put away activity of different HU type into the same bin.

So in this case system will allow to put away HU type – 0816, 0818 , 0820 , 0824 , DS , EP06 into the same bin having bin type – B304.

Additional prerequisites configurations are assignment of Storage bin type to Storage type, Handling unit type for each Storage type & HU type for each storage bin type.

Test case –

Inbound delivery document – 311820 is created in warehouse – 1100.

Staging bin – BL-LOSKADE is determined by the system where the Good receipt will happen.

Staging bin is determined based on the master data maintained for Staging area and door determination (Inbound) for particular WPT.

The Automatic packing happened with reference to pack spec and HU is created.

The Pack spec 22743 used by to create the HU can be seen in the HU.

The Pack spec is created for particular product and SC unit to have automatic packing.

The Target quantity of 30 PC can be packed in a Handling unit.

PACI – B300 is added in product master to find relevant storage type search sequence.

Search sequence – B300 can be determined based on PACI.

Storage type B300 is the first sequence in the storage type Search sequence. There is already a configuration in place for Pallet storage in storage type B300.

Good receipt was posted for HU and HU is available in Storage type B910.

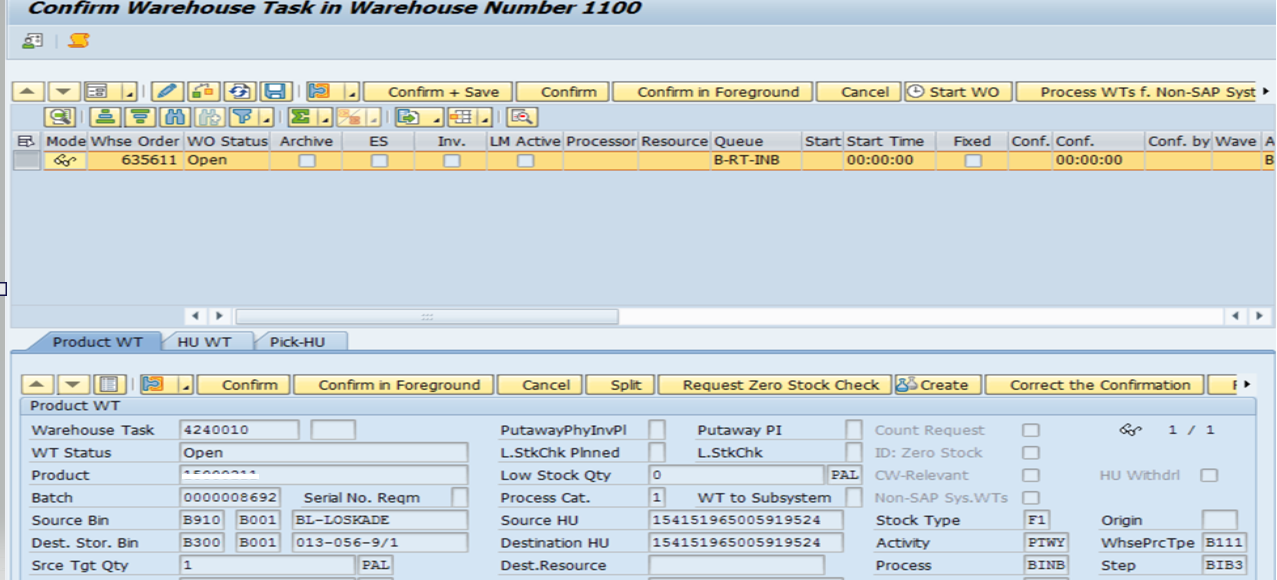

Created WT to complete the put away of HU.

After confirmation of WT, put away happened in the sub bin 013-056-9/1.

After first put away happened in Bin 013-056-9 , system created 4 Sub bins as per naming convention in the configuration for section key – 6.

013-056-9/1

013-056-9/2

013-056-9/3

013-056-9/4

The indicator for Storage bin subdivided can be seen.

The Bin sectioning is created after first put away to determine max no of HU’s – 4 and bin sectioning – 6.

The Sub bins created Inherits the Bin sectioning/No of Hu for Sub bins and Storage bin type – B304 from main bin.

Now Moved the only HU placed in a Bin -013.056-9/1 to Storage bin of Storage type - B910 with /N/SCWM/ADHU.

As a result of this action the Bin sectioning and Max no of HU’s details are deleted from main Bin – 013-056-9.

The Sub bin 013-056-9/1 does not exists now so it is evident that Sub bins are created for Pallet storage only after first HU is placed in the bin and Bin sectioning details/Sub bins are deleted after removal of last HU.

Summary:

In a nutshell , Pallet storage strategy(by HU type) allows to store Handling units with different Handling unit type into a Sub-Bins and Bin sectioning details are created once First HU is put away in a bin and it gets deleted automatically when the last HU in a sub bin is removed.

I hope that this blog post can be beneficial.

Best Regards,

Thanks to author Harish Patil