In the frame of this blog post, I’d like to give a detailed description of the configuration for Preallocated Stock functionality available in SAP EWM since the release SAP S/4 HANA 2020. This functionality is aimed to simplify the staging of components for production as well as fulfill the demand for materials in a specific area of the warehouse. In my article I’m going to consider a scenario with a Deconsolidation work center, check how the system behaves in a case of packed or unpacked stock, and also provide some references on required materials to succeed in your configuration.

Introduction

If you are already familiar with the functionality available in the WMS system you could probably find some similarities. The concept of preallocated stock in SAP EWM implies that in a specific area of the warehouse there is a demand which should be fulfilled urgently (e.g. Production Supply Area), in a best-case with a direct task from Goods Receipt Area, omitting the steps of stock processing, putaway, etc. So, to generate such a request in a warehouse we need to create the entry of preallocated stock for a specific product, storage bin, stock type (and other attributes of stock). A special node within the warehouse monitor has been introduced for that, the node has been added in the existing folder Stock and Bin -> Preallocated Stock. Once your preallocated stock entry is created it’s going to be considered for the specified product as a destination in the Goods Receipt process. If you work with products only a direct task is going to be created. For the packed stock, it can be required to send the handling units to Deconsolidation Work Center, for repacking the relevant stock for urgent allocation.

Scenario 1

In this scenario, we do not use handling units. so, the task is created directly from the goods receipt area to Production Supply Area where we have a demand for products. There is no additional effort on the processing of the stock, it is rerouted to another destination according to the request.

Scenario 2

In this scenario, we have packed stock on pallets, so it is required to repack the stock according to the demand. A first part of the stock goes to the storage as it is expected in a regular putaway procedure; a second part is routed to a new destination as requested for preallocated stock entry.

Configuration

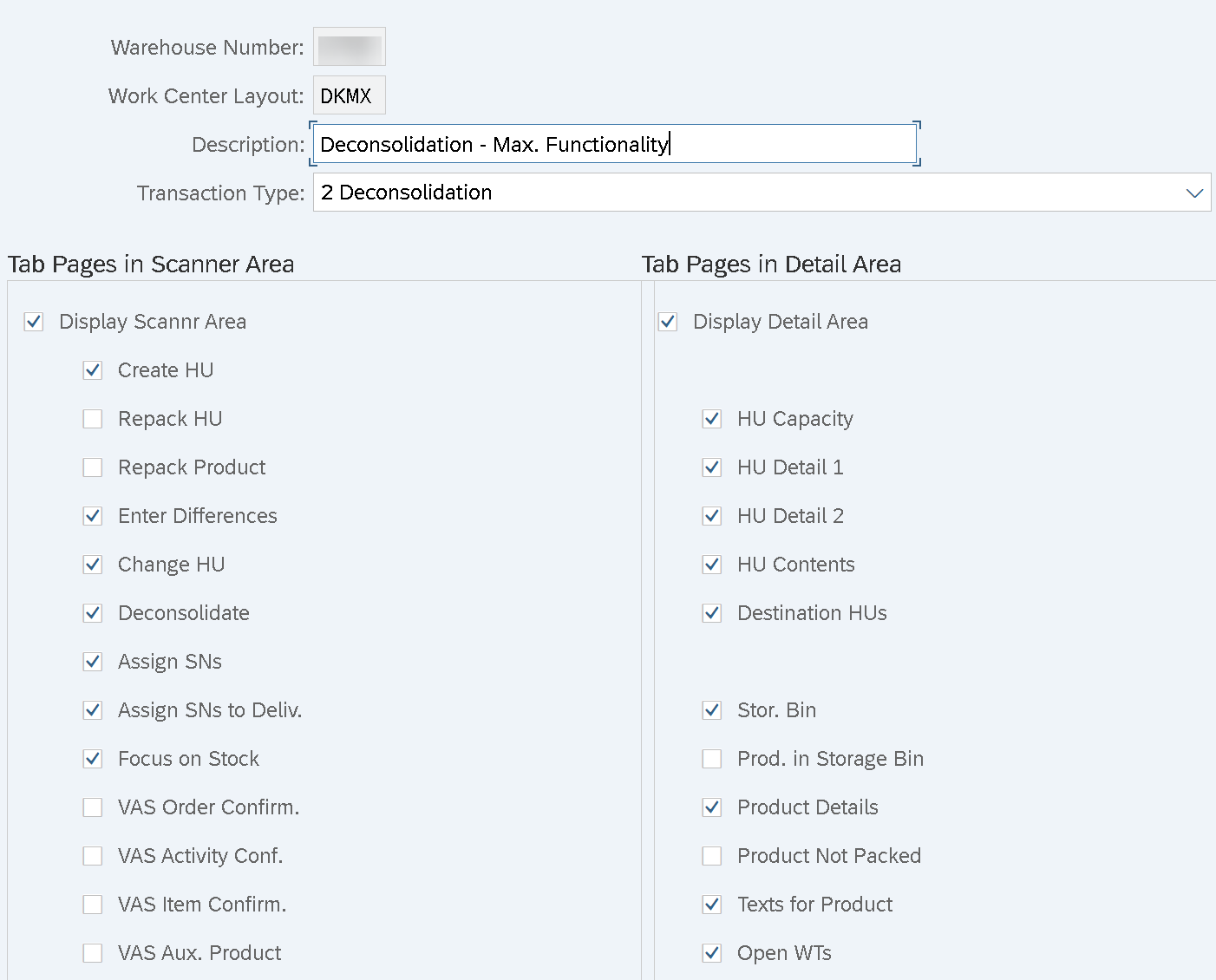

Create Layout for Deconsolidation Work Center

SAP IMG → SCM Extended Warehouse Management → Extended Warehouse Management → Master Data →Work Center → Specify Work Center Layout

To avoid any manual configurations, you can activate a BC Set /SCWM/WORK_CENTER_LAYOUT for getting the required layout or copy the settings from warehouse number 0001 (if exists).

Create Storage Type for Deconsolidation Work Center

SAP IMG → SCM Extended Warehouse Management → Extended Warehouse Management → Master Data → Define Storage Type

To avoid any manual configurations, you can activate a BC Set /SCWM/WE_STOR_TYPE for getting the required storage type or copy the settings from warehouse number 0001 (if exists).

Create Storage Section for Deconsolidation Work Center

SAP IMG → SCM Extended Warehouse Management → Extended Warehouse Management → Master Data → Define Storage Section

If you do not use the concept of moving stock to the outbound section after completion of processing it might be sufficient to create only a single section.

Create Storage bin for Deconsolidation

SAP Menu → Logistics → SCM Extended Warehouse Management → Extended Warehouse Management → Master Data → Storage Bin → /SCWM/LS01 - Create Storage Bin

If you have only one bin in your deconsolidation work center this step can be adjusted correspondingly.

Create External Process Step

SAP IMG → SCM Extended Warehouse Management → Extended Warehouse Management → Cross-Process Settings → Warehouse Task → Define Process-Oriented Storage Control

>External Storage Process Step

This step is only required if you do not have an external step for deconsolidation yet.

Check Warehouse Process Type for Repacking and HU movement

SAP IMG → SCM Extended Warehouse Management → Extended Warehouse Management → Cross-Process Settings → Warehouse Task → Define Warehouse Process Type

Check if warehouse process type 3040 exists, if not, create it>

Check if warehouse process type 3060 exists, if not, create it>

Create Deconsolidation Work Center

SAP IMG → SCM Extended Warehouse Management → Extended Warehouse Management → Master Data →Work Center → Specify Work Center Layout

To avoid any manual configurations, you can activate a BC Set /SCWM/WE_WC for getting the required work center or copy the settings from warehouse number 0001 (if exists).

Define Attributes of Work Center

SAP Menu → Logistics → SCM Extended Warehouse Management → Extended Warehouse Management → Master Data → /SCWM/TWORKST - Define Master Data Attributes

Create Storage Process for Putaway with Deconsolidation

SAP IMG → SCM Extended Warehouse Management → Extended Warehouse Management → Cross-Process Settings → Warehouse Task → Define Process-Oriented Storage Control

> Storage Process – Definition → Assign Storage Process Step

In my example, I copy a standard Storage Process INB1 and remove the steps which are not required.

> Process-Oriented Storage Control

Create Warehouse Process Type relevant for Preallocated Stock

SAP IMG → SCM Extended Warehouse Management → Extended Warehouse Management → Cross-Process Settings → Warehouse Task → Define Warehouse Process Type

Specify a storage process created on a previous step

Configure the determination of warehouse process Type and Putaway Strategy

In that step, we must guarantee that our Warehouse Process Type is determined in a Delivery item and the following Warehouse Task for Putaway can be created. I’m proposing the settings as required in my test scenarios, however in your landscape it might defer, or you may choose other possibilities to configure the same scenario.

SAP IMG → SCM Extended Warehouse Management → Extended Warehouse Management → Cross-Process Settings → Warehouse Task → Define Control Indicators for Determining Warehouse Process Types

SAP IMG → SCM Extended Warehouse Management → Extended Warehouse Management → Cross-Process Settings → Warehouse Task → Determine Warehouse Process Type

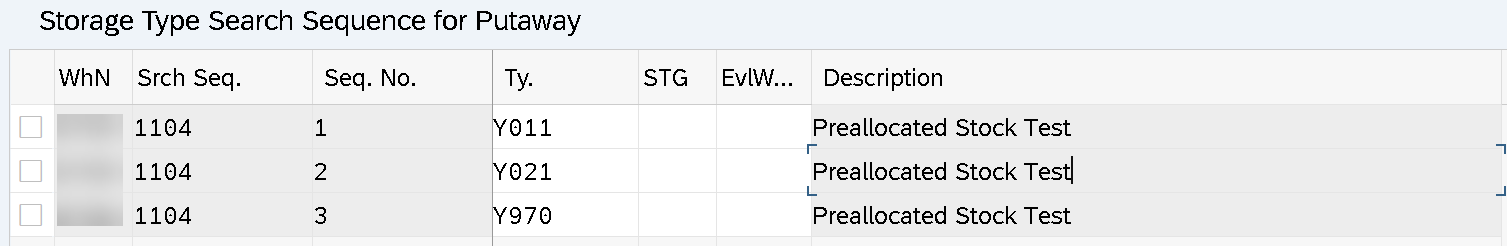

SAP IMG → SCM Extended Warehouse Management → Extended Warehouse Management → Goods Receipt Process → Strategies → Define Storage Type Search Sequence for Putaway

SAP IMG → SCM Extended Warehouse Management → Extended Warehouse Management → Goods Receipt Process → Strategies → Assign Storage Types to Storage Type Search Sequence

SAP IMG → SCM Extended Warehouse Management → Extended Warehouse Management → Goods Receipt Process → Strategies → Define Putaway Control Indicator

SAP IMG → SCM Extended Warehouse Management → Extended Warehouse Management → Goods Receipt Process → Strategies → Specify Storage Type Search Sequence for Putaway

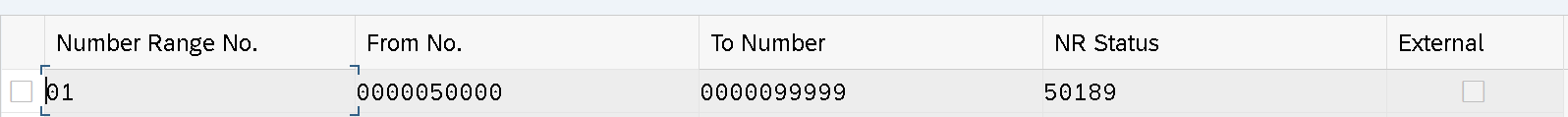

Check Consolidation Group for final activity areas

SAP IMG → SCM Extended Warehouse Management → Extended Warehouse Management → Master Data → Define Number Ranges

>Define Number Range Intervals for Consolidation Group

SAP IMG → SCM Extended Warehouse Management → Extended Warehouse Management → Goods Issue Process → Assign Number Range Intervals to Consolidation Groups

SAP IMG → SCM Extended Warehouse Management → Extended Warehouse Management → Master Data → Activity Areas → Assign Storage Bins to Activity Areas

Define Attributes for Deconsolidation

SAP IMG → SCM Extended Warehouse Management → Extended Warehouse Management →Goods Receipt Process → Deconsolidation → Specify Deconsolidation Station

*if other settings for deconsolidation are relevant for your scenarios, please check them as well

Sort the Bins for Activity Areas

SAP Menu → Logistics → SCM Extended Warehouse Management → Extended Warehouse Management → Master Data → Storage Bin → /SCWM/SBST - Sort Storage Bins

Adjust Warehouse Product

SAP Menu → Logistics → SCM Extended Warehouse Management → Extended Warehouse Management → Master Data → Product →/SCWM/MAT1 - Maintain Warehouse Product

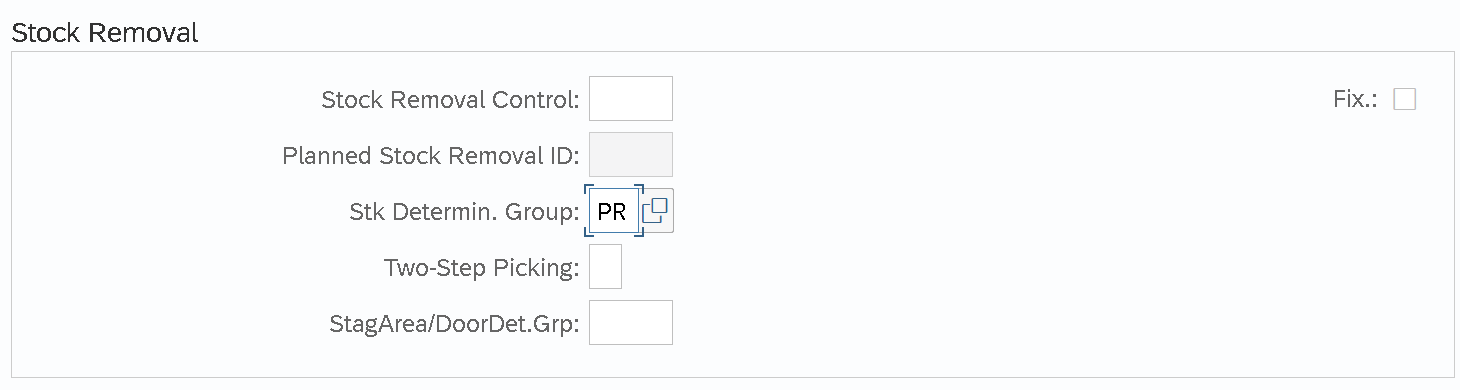

Other settings

>Staging Area and Door Determination

SAP Menu → Logistics → SCM Extended Warehouse Management → Extended Warehouse Management → Settings → Shipping and Receiving → /SCWM/STADET_IN - Staging Area and Door Determination (Inbound)

>Stock Determination

SAP IMG → SCM Extended Warehouse Management → Extended Warehouse Management → Cross-Process Settings → Stock Determination → Maintain Stock Determination Groups

SAP IMG → SCM Extended Warehouse Management → Extended Warehouse Management → Cross-Process Settings → Stock Determination → Configure Stock Determination

If this configuration is relevant, do not forget to add Stock Determination Group to Product Master

Demo Scenarios

Before the testing of our preallocated stock scenarios we need to create the entries of preallocated stock in Warehouse Monitor, for that we go to SAP Menu → Logistics → SCM Extended Warehouse Management → Extended Warehouse Management → Monitoring → /SCWM/MON - Warehouse Management Monitor, under the folder Stock and Bin → Preallocated Stock. Here we create the entry for preallocated stock as below:

*the same quantity for both scenarios

Scenario 1

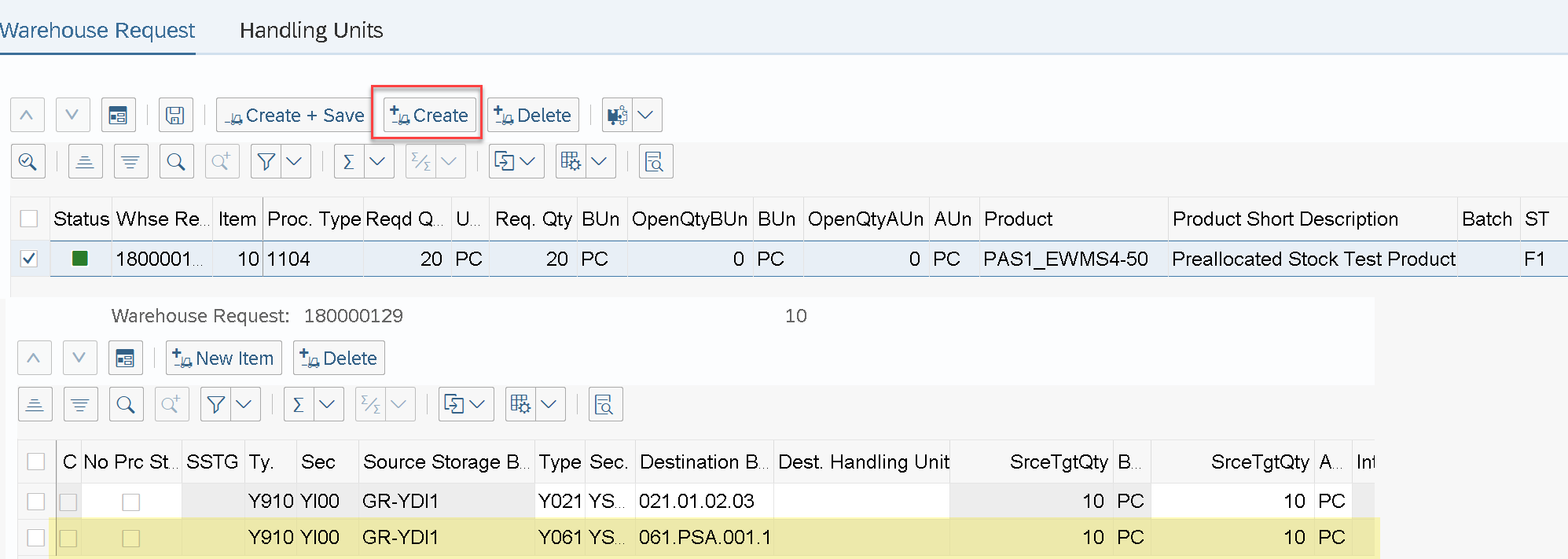

In that scenario, we move the stock from Goods Receipt Area to Production Supply Area according to the request defined for Preallocated Stock. To make an example more interesting I’m creating a delivery with a higher quantity (20PC) and part of the stock is still going to the storage according to the regular procedure (10PC). Let’s look at the steps of this Scenario:

Inbound Delivery

Inbound Delivery Item

Warehouse Task Creation

As requested, part of the stock goes directly to Production Supply Area

![]()

2 product warehouse tasks have been created.

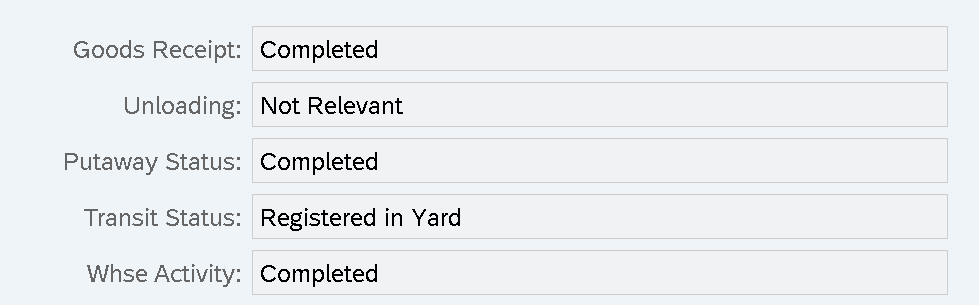

Warehouse Task Confirmation and Delivery Completion

After confirmation of both tasks, I can see the change in required preallocated stock, and inbound delivery is completed.

Preallocated Stock Entry has been removed, as no further request exists.

Scenario 2

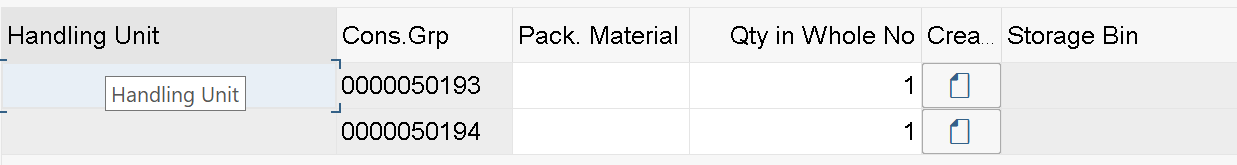

In that scenario, we receive packed stock on a pallet and distribute it according to preallocated stock requirements after deconsolidation. The delivery quantity is 20PC, and a request for preallocation is created for 10PC. This scenario is combined with a standard scenario for deconsolidation and only the part of alternative bin determination is added. Let’s look at the steps of this Scenario:

Inbound Delivery

Inbound Delivery Item

Packages in Delivery - 2 Cartons on 1 Pallet

Warehouse Task Creation

![]()

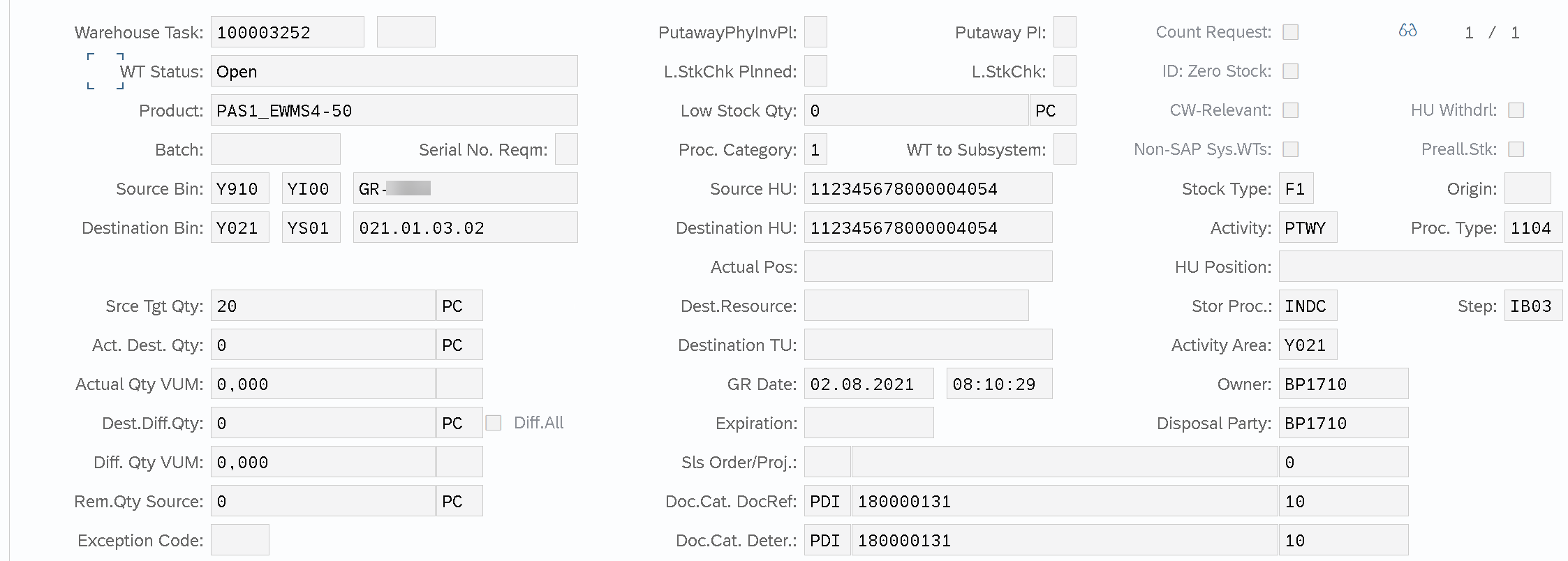

Confirm Movement to Deconsolidation Work Center and Repack Stock as Requested

As for every task we have a different destination consolidation group we need to repack it manually or automatically.

During the consolidation, I remove the boxes from the pallet and close the step of Deconsolidation to unlock warehouse tasks for further processing.

Two warehouse tasks are available and can be confirmed. The deconsolidation step is set as Completed.

![]()

This Task is also can be seen from Preallocated Stock View

After completion of the process, the entry for the preallocated stock is removed, delivery is completed.

Stock in PSA is increased with 10 PC more and now it is 20PC in total.

Scenario 2.1

In this short addition to scenario 2, I’d like to show that nothing happens with stock if there is no record for preallocation. As there is no need to do any deconsolidation activities the step of deconsolidation is going to be omitted.

The process itself is equal to the main Scenario 2, with the only exception that Preallocated stock is not created. I pack the delivery in the same way and create Warehouse Tasks

But this time stock goes directly to the destination (for the same storage process), the step of Deconsolidation is removed as it is not required.

Important Notes and References

- 2967019 – Preallocated Stock: Fixes

- 3051033 – Pre-allocated Stock: Bug Fix Deconsolidation with Nested HU and after Deletion and Retrigger ‘Create’ WTs result is Inconsistence

- Preallocated Stock on SAP Help – https://help.sap.com/viewer/9832125c23154a179bfa1784cdc9577a/2020.000/en-US/e412a50b55494e86b8bd21e7b6c9e08e.html

- Deconsolidation on SAP Help https://help.sap.com/viewer/9832125c23154a179bfa1784cdc9577a/2020.000/en-US/33cdcb53ad377114e10000000a174cb4.html?q=deconsolidation

This blog post is based on my personal investigations in the area of preallocated stock and configured as given in a test system. All the screenshots captured and pictures presented for demo purposes and may defer in your production environment. I hope you enjoy this article and it helps you to succeed with the same scenarios in your system. If you still have questions please do not hesitate to write them in the comment area below. Any feedback would be very much appreciated. Good Luck!

Thanks to author Andrey Andrian