Introduction:

In this blog post you will learn about the Bulk Storage Put away Strategy in SAP EWM. There are some materials that require a large amount of storage space usually stored in bulk Storage areas and in this type of scenarios bulk put away strategy is used. Examples: beverages, tyres and glass products etc.

In this case, the storage bins in bulk storage are separated by lines on the warehouse floor. Each bin generally holds only one kind of product. For instance, soft drinks of specific variety or similar pallets or containers are stacked together. Based on the stacks/Stack height & max.Hu’s value which attributes to its physical structure ,the system creates a block structure or partition for each storage bin.

Solution Approach:

The below mentioned configuration steps can be employed to achieve this functionality:

- Create a bulk storage type by enabling the required settings to implement Bulk Strategy using the below mentioned node.

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Master Data -> Define Storage Types.

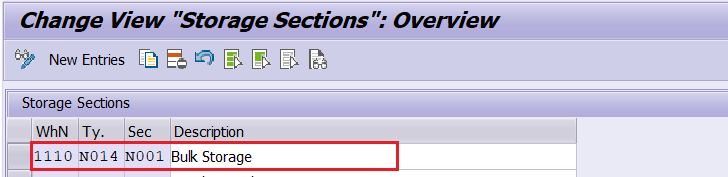

- Create a storage section using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Master Data -> Define Storage Section.

- Create a storage bin type using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Master Data -> Storage Bins->Define Storage Bin Types.

Note:

- If there is any particular resource used to access this type of bin, then we need to mention the Bin access type in the node as “Define Bin Access Types”.

- Also, if we want to auto generate the storage bin, then we need to mention the storage bin structure.

- Generate activity area using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Master Data -> Activity Areas->Generate Activity Area from Storage Type.

Sort sequence can be mentioned in the node “Define Sort sequence for Activity Area” to sort the storage bin in a particular order.

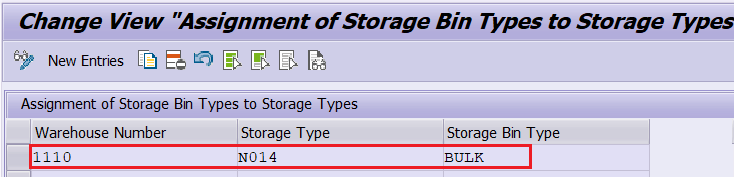

- Map the storage type and storage bin type using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Goods Receipt Process -> Strategies-> Storage Bin Determination->Assign storage bin types to storage types.

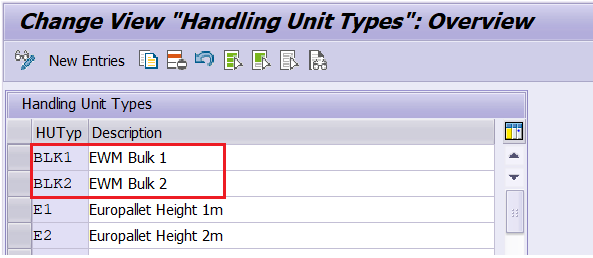

- Define HU type using the below mentioned node:

IMG Path – SPRO -> IMG -> Integration with Other SAP Components->Extended Warehouse Management->Additional Material Attributes->Attribute Values for Additional Material Master Fields->Define Handling Unit Type.

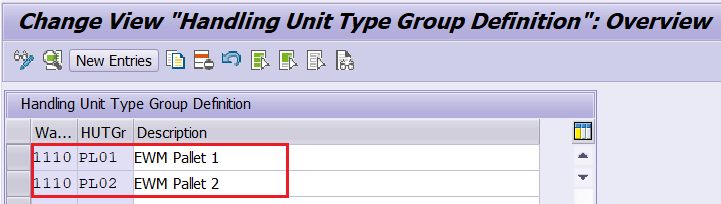

- Define HU type Groups using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Cross-Process Settings -> Handling Units->Basics->Define HU Type Groups.

- Define HU Type for the respective warehouse number and assign the HU Type Group using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Goods Receipt Process -> Strategies-> Storage Bin Determination->HU Types->Define HU Types for each warehouse number and Assign HU Type Group.

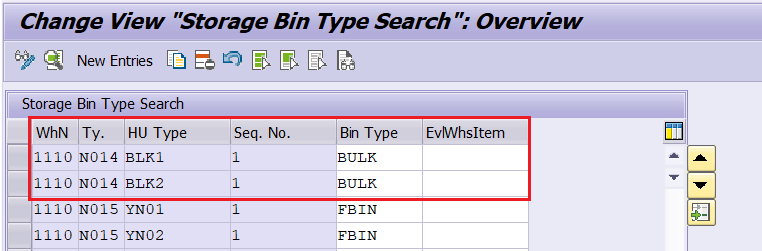

- Assign the HU Types for this bulk storage type (N014) using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Goods Receipt Process -> Strategies-> Storage Bin Determination->HU Types->Define HU Types for Each Storage Type.

- Map the storage bin type for the respective HU type using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Goods Receipt Process -> Strategies-> Storage Bin Determination->HU Types->Define HU Types for Each Storage Bin Type.

- Mention the storage type control for this Bulk Storage using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Goods Receipt Process -> Strategies-> Put away Rules->Storage Behavior: Bulk Storage>Storage Type Control for Bulk Storage.

Control Parameters:

- Mention if the partial quantities are allowed or not for this respective storage type.

- The storage bin will be blocked for put away once the first stock removal has taken place. In addition, we can specify the number of days after the first put away, after which the storage bin should be blocked for put away.

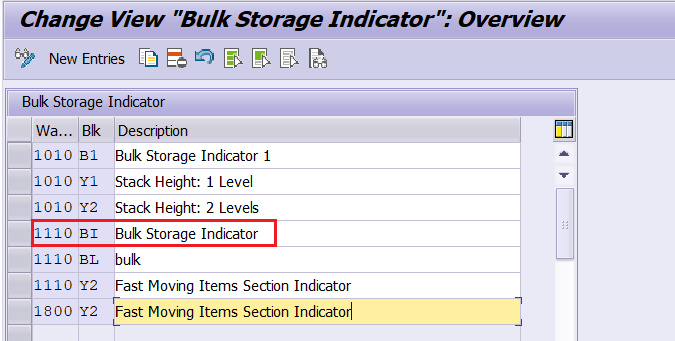

- If we want to store a particular product in a particular order, then we need to create a Bulk Storage indicator and assign it to respective product master. Bulk Storage indicators will be created using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Goods Receipt Process -> Strategies-> Put away Rules->Storage Behavior: Bulk Storage>Define Bulk Storage Indicators.

- Define bulk structure by specifying the Warehouse number, Bulk Storage type, storage bin Type,HU type, Bulk storage indicator, number of stacks, the stack height, and the number of handling units (Hus).

The maximum number of HUs is the multiplication of number of stacks and stack height. So, in this case, a bin will carry a maximum of 12 Hus for the HU type BLK1 and it will carry a maximum of 6 Hus for the HU type BLK2.

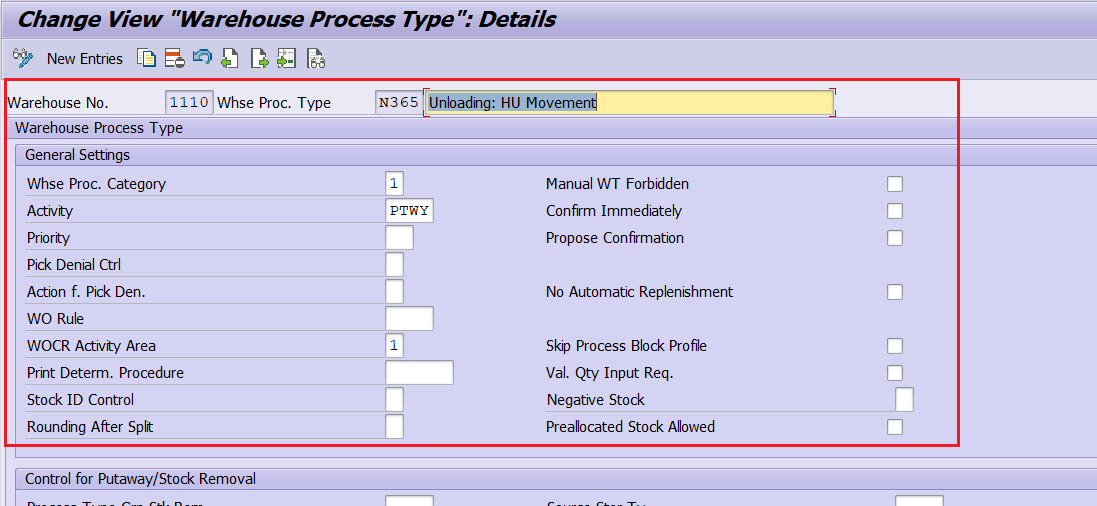

- In this case goods are unloaded to staging area before reaching the final put away. To achieve each movement, a warehouse task is to be created and for every warehouse task creation a warehouse process type needs to be defined.

Create warehouse process type using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Cross-Process Settings -> Warehouse Task -> Define Warehouse Process Type.

Warehouse Process Type-N365 (To move Goods from Door to GR Zone).

Warehouse Process Type-N011 (To move Goods from GR Zone to Final put-away bin)

- In the inbound delivery, the warehouse process type: N011 should be assigned to the delivery item level. To determine this warehouse process type, a control indicator should be defined and assigned to the respective warehouse process type.

Create control indicators using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Cross-Process Settings -> Warehouse Task -> Define Control Indicators for Determining Warehouse Process Types.

Assign this control indicator to the respective document type, item type and warehouse process type using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Cross-Process Settings -> Warehouse Task -> Determine Warehouse Process Type.

- In the above step a warehouse process type is defined for both unloading and put away following which a Process-oriented storage control (POSC) is defined to execute this movement in a sequenced way.

Create External Storage Process Step using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Cross-Process Settings -> Warehouse Task -> Define Process-Oriented Storage Control.

Next map the source and destination information along with warehouse process type for those External steps created above.

Now define Storage Process as shown below:

Then assign these External steps to the Storage Process as shown below:

Finally assign this Storage process: NI01 to the warehouse process type: N011 using the below mentioned node:

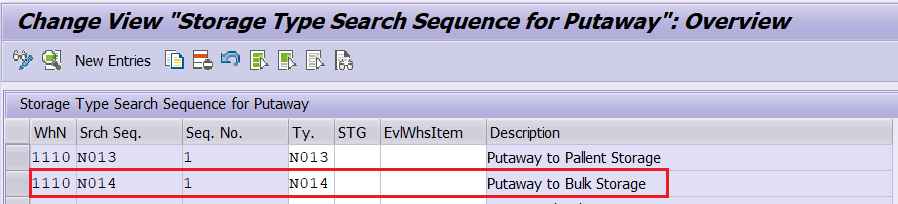

- Create a storage type search type search sequence using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Goods Receipt Process -> Strategies -> Define Storage Type Search Sequence for Put away.

- Assign storage types to storage type search sequence using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Goods Receipt Process -> Strategies -> Assign Storage Types to Storage Type Search Sequence.

- Define Put-away control indicator using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Goods Receipt Process -> Strategies -> Define Put-away Control Indicator.

- Maintain the determination of storage type search sequence for Put-away using the below mentioned node:

IMG Path – SPRO -> IMG -> SCM Extended Warehouse Management -> Extended Warehouse Management -> Goods Receipt Process -> Strategies -> Specify Storage Type Search for Putaway.

- Create packaging material by mentioning the HU Type using the t-code:MM01.

- Create packaging specification for the Product: 904 by mentioning the packaging materials and qty using the t-code:/SCWM/PACKSPEC.

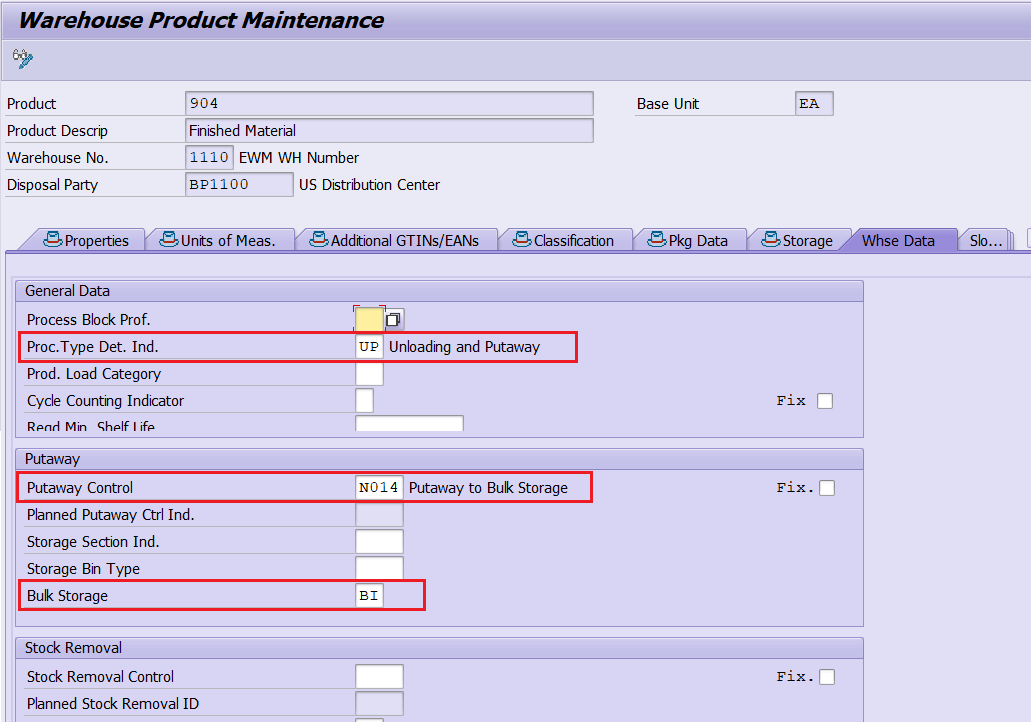

- Maintain the warehouse product master by mentioning the process type determination indicator, Put-away control indicator and Bulk Storage indicator using the transaction code:/SCWM/MAT1.

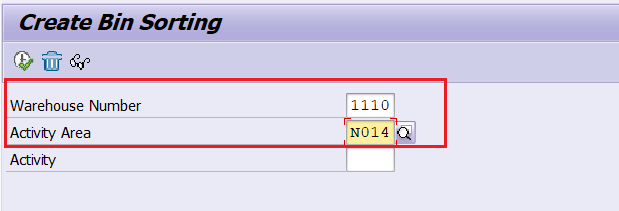

- Create a storage bin using the t-code:/SCWM/LS01 and perform the bin sorting using the t-code:/SCWM/SBST.

Testing:

- Inbound delivery is created.

- In the delivery screen, create warehouse task manually by clicking on CREATE button and then SAVE.

Inbound delivery screen can be reached using the t-code:/SCWM/PRDI.

- Warehouse task can be viewed in the monitor screen using the transaction code:/SCWM/MON.

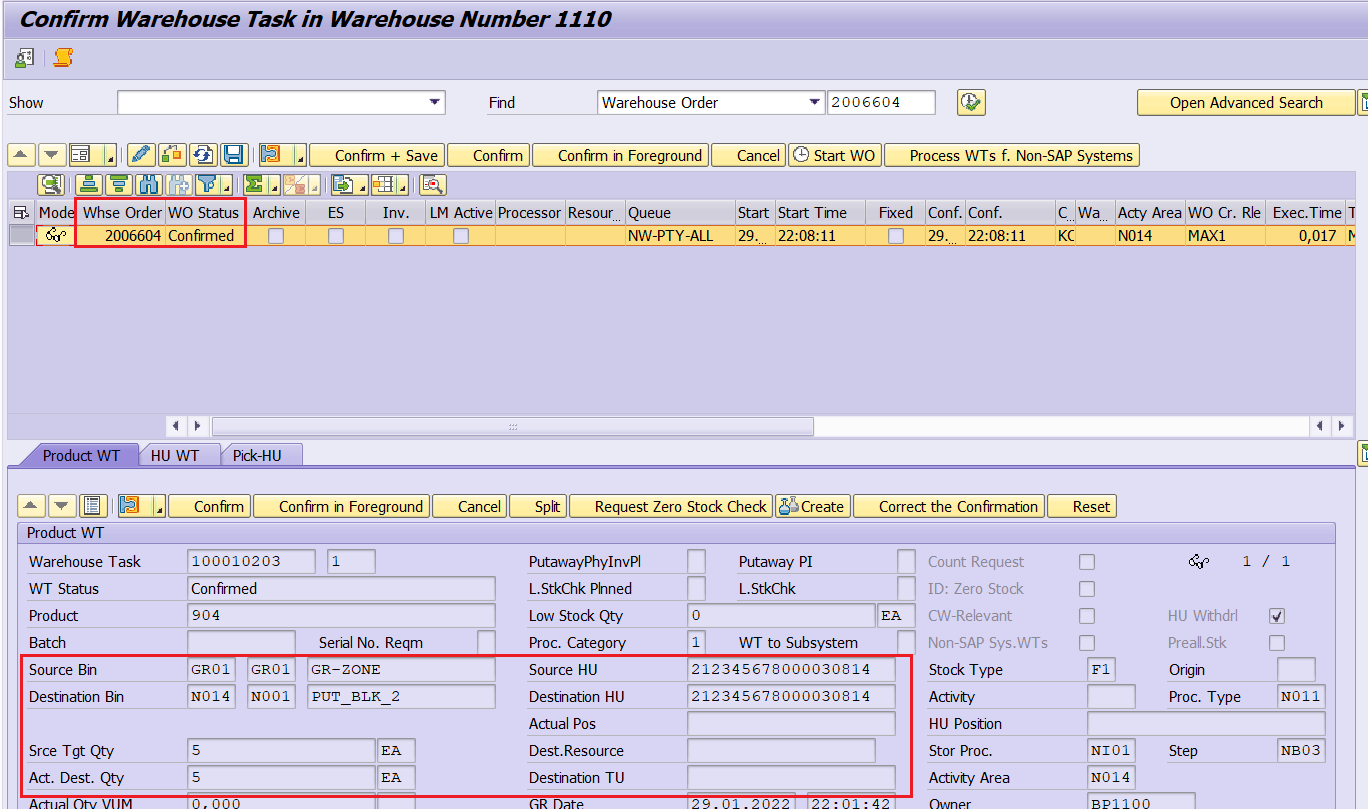

- Confirm the Warehouse order using the transaction code:/SCWM/TO_CONF so that the Handling unit will be moved from Door to the GR zone and it consequently enables a put-away warehouse order to perform the put-away activity.

- Finally, confirm the warehouse order created using the transaction code:/SCWM/TO_CONF so that Handling unit will be moved from GR-Zone to the final Put-away bin.

- The inbound delivery is marked as completed once the goods are moved to the final put away bin.

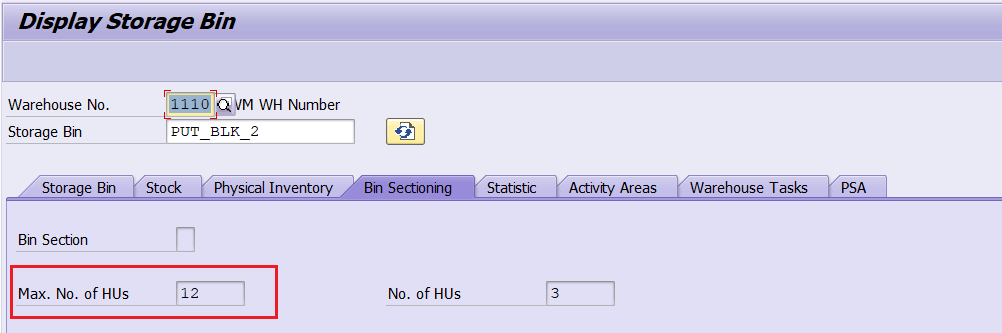

- The bin sectioning will be updated in the storage bin after the first put away. In this case this storage bin holds a maximum of 12 Hu’s and currently it contains only 3 Hu’s.

Conclusion:

This blog post walks you through various steps involved in Bulk Storage Strategy with test results.

Thanks to author Krishnakumar Chokkar