Definition-

The target production supply area (PSA) defines the production supply area of the next production step.It is used if a semifinished product remains in production and is needed for a subsequent production step.

Dependencies-->If the storage location, where the semifinished product is placed upon order confirmation or goods receipt, is not managed by the warehouse, the field is only for information character.

If the storage location, where the semifinished product is placed upon order confirmation or goods receipt, is managed by (EWM), the target PSA is used to determine the destination bin during warehouse task creation upon synchronous goods receipts.

The following prerequisites must be fulfilled:

- For discrete manufacturing, the production scheduling profile used for the order is set up for Post Synchronously to Bin.

- For repetitive manufacturing, you have selected Post Synchronously to Bin in the repetitive manufacturing profile

- For the semifinished product a control cycle is defined for the target PSA and the destination bin has been assigned to the control cycle

- The automatic warehouse task creation upon receipt is active either for the storage type of the goods receipt bin or for the warehouse process type.

-->This blog replication steps will follow discrete manufacturing integration with SAP EWM and how Target PSA can be leveraged for sub-assemblies to be consumed directly from next PSA instead of movement to final bin.

Use

The Target PSA field is used to determine the destination bin via the control cycle of a semifinished product for the warehouse task towards the next PSA in the manufacturing process. With this option you can optimize your production process as the semifinished products do no longer require a putaway and additional staging step to the next production line. The destination bin for warehouse tasks upon goods movement is used to define where the products are to be put away once they are received in the warehouse.

Replication Steps:

- Production Version:Assign PSA in Target PSA field in Production Version of Product( C223)

- Control Cycle:Assign Target PSA bin in Control cycle( Product dependent PSA) in LPK1. Ensure to have Material Staging Indicator (MSI) as 0

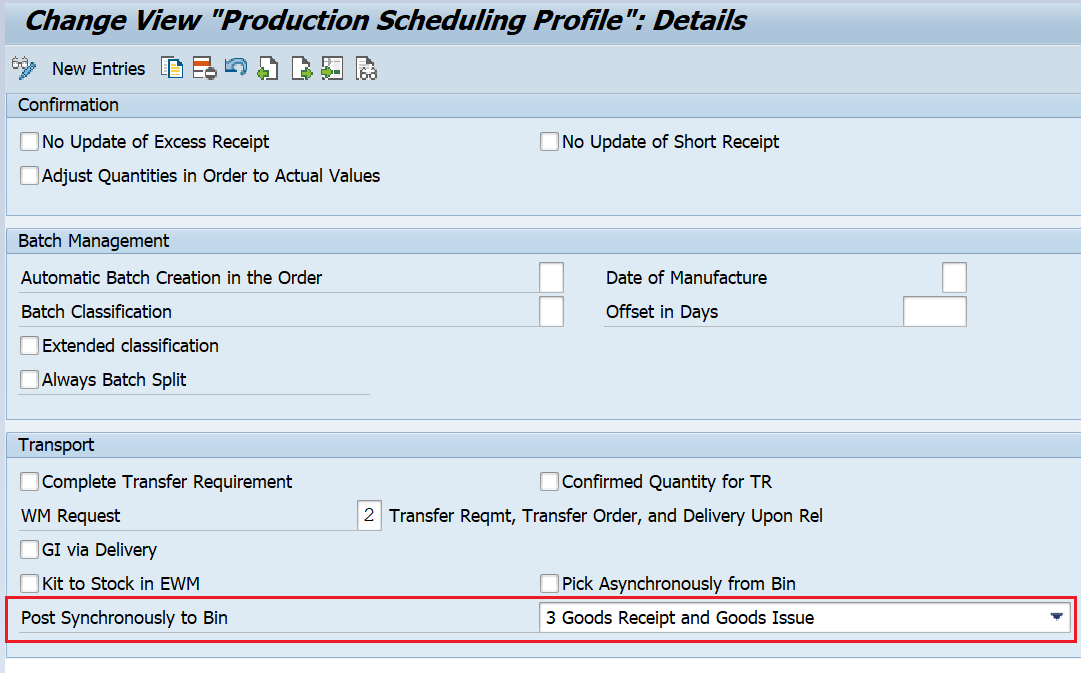

- Production Scheduling Profile: Ensure to activate synchronous GR to Bin.

- WPT determination: Assign the correct WPT without delivery type/Item types based on Product characteristics whether is HU or Non HU.. In this example, Semifinished will be received in Packed form.

- Create a Production Order-

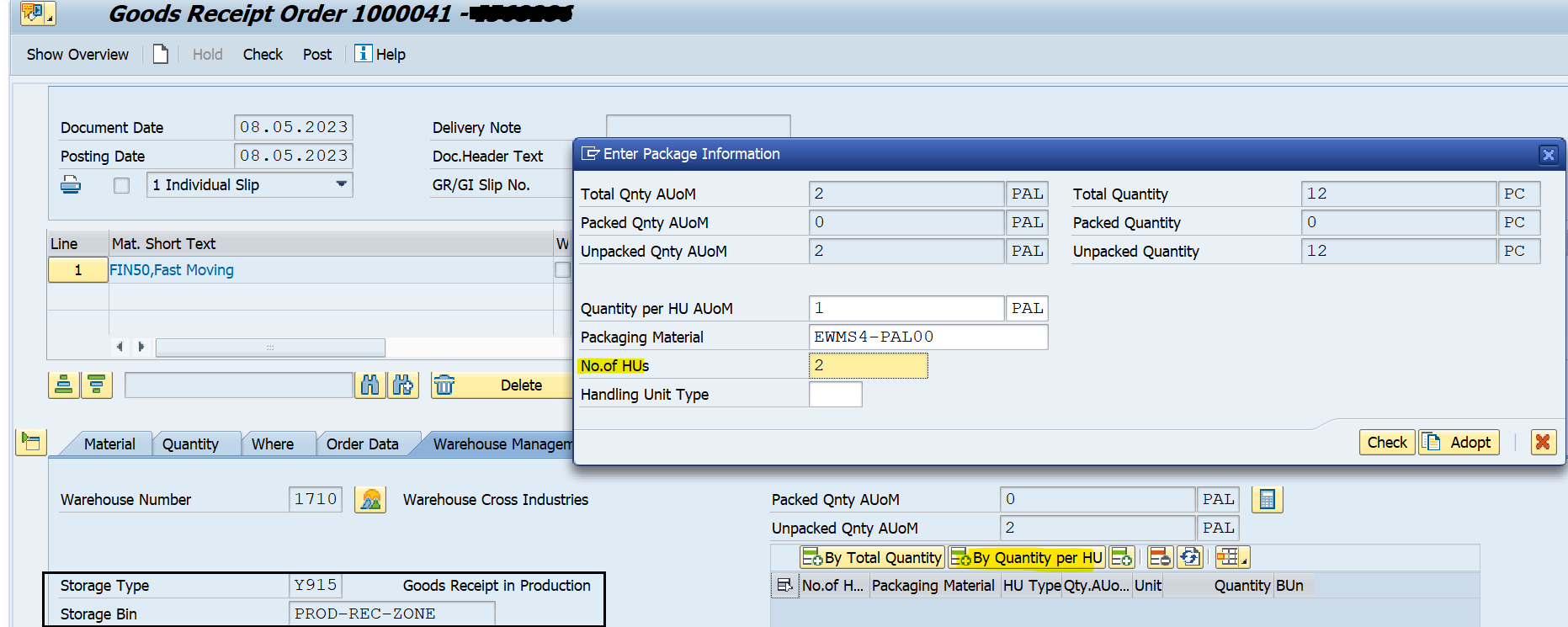

- MIGO- Carry out Production Order HU Level GR, 2 HUs have been received.

- Check Production Order- Documented Goods Movement CO03. 2 Pal have been updated in Delivered qty field

- Warehouse Management Tab- Check the WM tab of Material document.

- Automatic WT created- HU WT has been created for 2 HUS at Target PSA

Warehouse Monitor- Check the stock of Semifinished HUs, its been posted at Target PSA bin

Thanks for reading. All the information and contents is purely based on my research and is replicated on S/4 HANA Embedded EWM Sandbox system.

Thanks to author Shailes Mishra