In this article I would like to present couple of option how to manage Shipping and Receiving topic in EWM with integration to ECC to create Transportation unit (TU) and Vehicle (VEH).

For more details please follow the documentation provided by SAP and available here.

Use of Transportation unit (TU) or vehicle (VEH) in EWM can be handled in different ways:

- Manually created TU or VEH not integrated with any other component

- Automatically created TU or VEH based on data coming from delivery (inbound or outbound) from ECC

- Automatically created TU or VEH based on data coming from shipment (inbound or outbound shipment) from ECC

- Shipment creation in ECC based on TU or information in EWM

- Automatically created TU or VEH based on integration with Transport Management (TM)

First option is a fully manual solution where user needs to create TU or VEH in EWM (transactions: /SCWM/TU or /SCWM/VEH). Option fifth is the most complex and require integration with SAP TM system but as well offers the most including for example creation of shipments or bill of ladings in EWM. In this article I would like to focus on second, third and fourth options to create automatically Transportation unit.

Despite of used option (here understand as second, third or fourth option) basic configuration to link the packaging material to the means of transport is needed.

- Create new means of transport

SPRO -> EWM -> Master Data -> Shipping and Receiving -> Define Means of Transport

Important is to define the standard code for means of transport that is not used before for any other record because based on this field matching is done.

- Configure new means of transport including

SPRO -> EWM -> Cross- Process Settings -> Shipping and Receiving -> General Settings –> Define Control Parameters for Forming Vehicles/Transportation Units

In this step you add your new means of transport and couple of parameters like number range, default owner plus action profile (standard for TU is /SCWM/TU)

- Define new packaging material with category A – Means of transport

In customization under SCM Basis -> Pack -> Handling Units, you can define new Packaging material types and set category of the PM to A – Means of Transport, Transport Element, Transport Unit.

- Create a packaging material in EWM for means of transport

You can as well send a material from ECC system via CIF. Important is to set on Pkg Data tab, packaging material type to the one created step before, in my case MTR2.

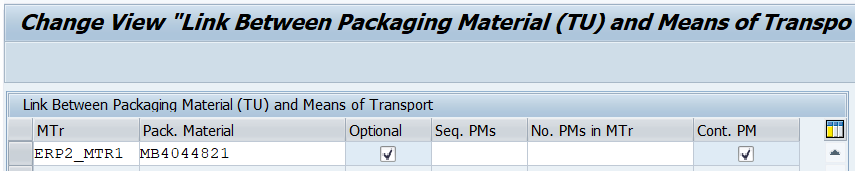

- Link Packaging Material with Means of transport – TCode /SCWM/PM_MTR

The final step to link means of transport with a packaging material used to create transportation unit. Column with Cont. PM. - If you set this indicator, the system creates a transportation unit (TU).

This was the basic customization needed in despite of selected option to use.

Option 2 – Create transportation unit (TU) or vehicle (VEH) based on transportation data in delivery sent from SAP ECC.

The simplest option to generate automatically TU or VEH based on transportation data filled in in delivery in ECC. This option is valid for inbound and outbound processing. As a result TU or VEH is created in EWM and assigned to delivery.

Customizing:

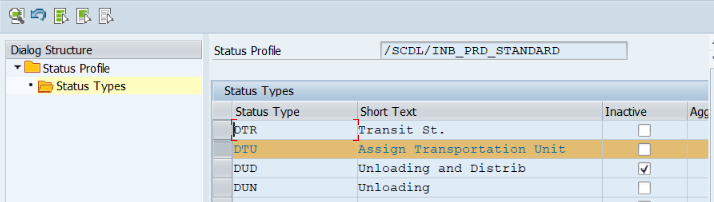

- The DTU status Assign Transportation Unit is active for the delivery type and item type used in SAP EWM. Example of standard inbound delivery profile /SCDL/INB_PRD_STANDARD.

- The PPF active action (in my case Z_VEH_CR) that will call method /SCWM/WHR_CREATE_VEHICLE in the action profile assigned to the delivery type in SAP EWM. Of course valid condition record is needed for the action defined.

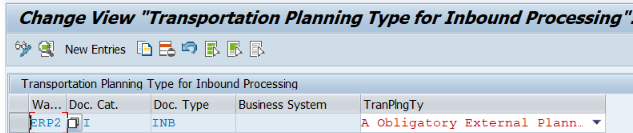

- Integration with Transportation

The most important step to set up how the transportation is managed. Following options are available which have significant influence on how data coming from ECC delivery are going to be used. Customizing is done per delivery.

- No Obligatory planning - data sent from ECC within delivery are used to create TU.

- A – Obligatory External Planning in ERP – data sent from ECC within shipment are used to create TU.

- B – Obligatory Internal Planning in EWM – created in EWM TU is integrated with ECC to create a shipment based on TU data.

Example of inbound processing

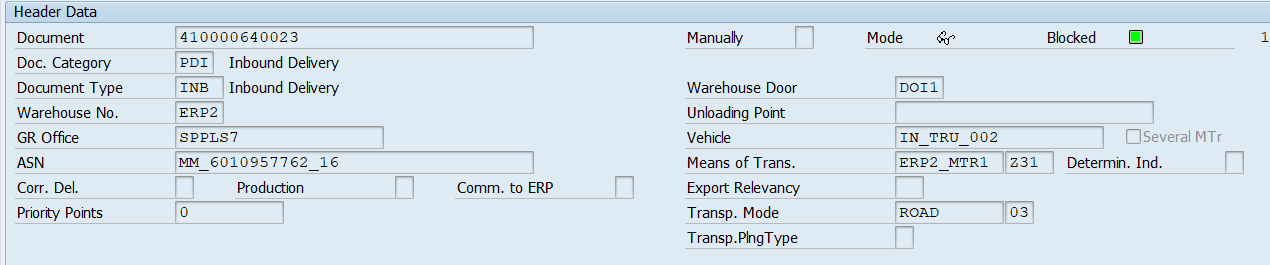

During creation of IDN in ECC means of transport needs to be populated with packaging material type that corresponds to EWM means on transport packaging type. Means of Transport ID field will be used by system to generate external TU identification. Fields are as well accessible on the header level of delivery in the shipment tab.

During processing of inbound queue in EWM that contains inbound delivery from ECC, information about means of transport and the means of transport ID are populated to EWM inbound delivery notification and to inbound delivery itself and used to determine EMW means of transport.

Then based on PPF action (configured as prerequisite) new TU has been created with parameters respective to configuration and can be used for delivery processing.

Option 3 – create Transportation unit (TU) or vehicle (VEH) based on shipment documents in SAP ERP.

This option is based on shipment document created in ECC. The shipment document contains delivery (or multiple of them) and the shipment document is assigned with article used as means of transport. Shipment is sent as output to EWM via Idoc (Idoc: SHPMNT) and generates automatically TU or VEH based packing material type used. This option is valid for inbound and outbound processing. As a result TU or VEH is created in EWM and assigned to delivery.

Customizing:

In ECC and EWM setup Idoc communication (both inbound and outbound) for following Idoc type SHPMNT05 – Shipments.

For the TU or Vehicle or more precisely for the means of transport that you are going to create, the action profile defined for it, assign actions:

- /SCWM/SR_SEND_SHPMNT

- /SCWM/SR_SEND_SHIPP

- Both action are used only in case of outbound deliveries and are useless in case of inbound deliveries

Integration with Transportation

As explained before about the integration with transportation, configuration needs to be changed to A – Obligatory External Planning in ERP – data sent from ECC within shipment and used to create TU.

Example of inbound processing

As a first step, inbound delivery is created in ECC and distributed to EWM. Even if transportation data are entered in IDN just like for option 2 they are ignored in the inbound queue processing. Later on in ECC shipment document is created and packed. HU is linked with TU via packaging material type and EWM means of transport as described in prerequisite configuration.

As the result of shipment distribution to EWM, transportation unit is created in EWM and assigned to delivery. Described option is valid for inbound and outbound processing.

Option 4 – create shipment document in ECC with assigned HU based on TU assigned into outbound delivery order in EWM.

This option is valid only in case of outbound processing. In EWM, TU or VEH is created manually and assigned to ODO. When PGI is posted for TU or assigned outbound delivery in EWM, Idoc to create shipment (Idoc: SHPMNT05) is sent to ECC. Based on inbound processing of the Idoc, shipment is created and HU with means of transport article assigned.

Customizing:

In ECC of course shipping type and packing material needs to be configured.

In EWM beside all mentioned configuration for Option 2 and Option 3 default values for shipments to be created out of EWM.

SPRO - > EWM - >Interfaces -> ERP Integration -> Transportation -> Define Default Values for Idoc Outbound.

Keep shipment open means that message sent to ECC to create or update shipment will not contain shipment end execution date and allow monitoring transportation process.

Integration with Transportation

As explained before about the integration with transportation, configuration needs to be changed to B – Obligatory Internal Planning in EWM – created in EWM TU is integrated with ECC to create a shipment based on TU data.

Example of outbound processing

As a first step, outbound delivery is created in ECC and distributed to EWM. Then manual creation of TU is executed (with /SCMW/TU) and assignment to ODN.

Then TU is checked in Checkpoint and loading can start. After PGI has been posted outbound Idoc with shipment is triggered from EWM to ECC.

Thanks to author Maciej Jarecki